Contact us

A good plastic feeder will help you cut costs and expan […]

A good plastic feeder will help you cut costs and expand your manufacturing capabilities. A Plastic feeder can be used for extrusion, injection molding, or blow molding. It is easy to use, reliable, and easy to maintain. The controls are user-friendly, which means that you will get accurate results every time. If you have questions, please contact our customer support team. We are happy to answer any questions you may have. We also offer a free 30-day trial period.

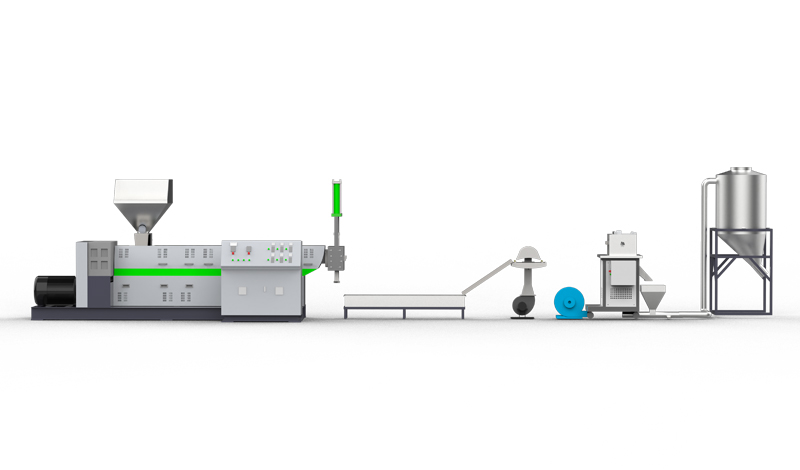

The best plastic feeders can be found in many varieties and can meet your specific requirements. A typical plastic feed system has a neckpiece that mounts under the main material hopper. A feed screw assembly is used to measure additive materials. It is operated by a solid-state controller to set the feed rate. It has the capability to handle feed rates ranging from a few ounces per hour to over 5,000 pounds per hour.

A Plastic feeder can feed additives to a single screw extruder. The feed screw assembly is installed directly underneath the main material hopper. A solid-state controller controls the speed of the motor. A plasticolor feeder can feed a wide variety of bulk materials, from a few ounces to 5,000 pounds per hour. The precision feed screws allow the unit to be used for a wide range of applications.

A Plastic feeder is installed on a neckpiece under the main material hopper. The feed screw assembly is used to meter additive materials. The machine is controlled by a solid-state controller, which regulates the speed of the motor. The Feedolor feeds a range of materials from a few ounces to five tons per hour. The feeder is also equipped with an adjustable feed hopper. If you need a large-scale feeder, consider a LIW feeder. It features a large hopper, refill and discharge device, and a controller. You set the setpoint to the rate of material feed to ensure the accuracy of the product.

A single screw extruder is a popular type of plastics feeder. The feed rate of a single screw extruder depends on its density. A twin screw extruder requires a high-precision feed rate. A Twin-screw feeder has precision feed screws that are adjustable based on the materials' density. In addition, it is easy to adjust the speed of a twin-screw extruder.

Industrial Plastic Feeders come in different configurations and designs. A single screw feeder is typically operated by a single screw. It uses a volumetric feeder. Gravimetric feeds are more precise, and can react to fluctuations in bulk density and material flow. It can feed several pounds per hour. The unit is designed for small or large-scale feed rates. It features a precise feed screw that allows for adjustable feeding rates.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3