Contact us

The Benefits of Using a Plastic Pelletizing Line A plas […]

The Benefits of Using a Plastic Pelletizing Line

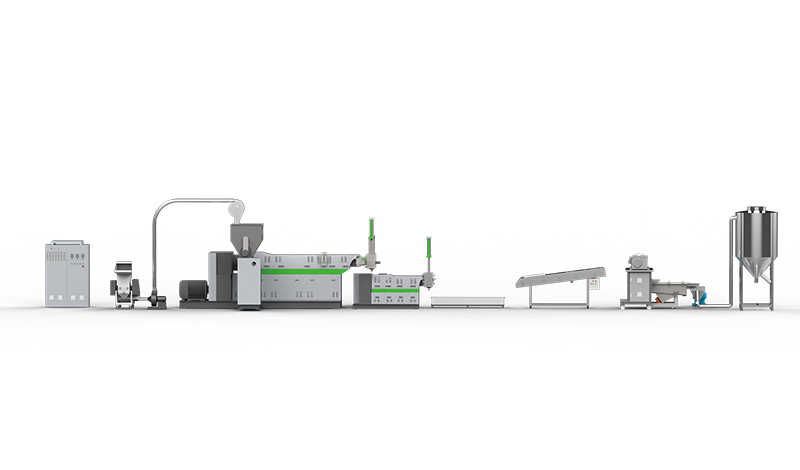

A plastic pelletizing line is a production process that produces small granules from a variety of materials. These materials include PP PE, PET, PS, and EPS. This article will discuss the advantages and disadvantages of each type of plastic pellet, as well as the benefits of using one. Once you have selected a plastic pelletizing line, the next step is to choose a suitable extruder. There are many advantages to using a granulation extrusion line over a traditional one.

PP PE PP PE

A PP PE plastic pelletizing line is a complete system that combines international advanced recycling technology with the actual application conditions of waste plastic. Generally, it is designed for the recycling of waste PE film, including agricultural film, PE plastic bags, and packaging film. The end product is a plastic pellet, which can be further processed to produce PE plastic sheets, drainage pipes, and even boards. PP PE plastic pellets have a variety of applications, and can help the environment.

A PP PE plastic pelletizing line can be customized to meet the specifications of different companies. It can process a variety of plastic films, from granular to pelletized form. The main components of a plastic pelletizing line are a compounding extruder, two-stage pelletizer, and extruder. Some plastic pelletizing lines have a vacuum exhaust system, which allows for better particle density and sol mixing effect. Others feature a forced feeding system to increase production capacity. Other features of a pelletizing line include color mixing granulation and a high torque.

PET

Whether you're in the market for a new or refurbished line, a PET pelletizing line can help you recycle waste PET bottles. The recycling process is particularly important for areas where PET bottles are used frequently as fiber textile raw materials. These bottles are used for beverage containers, tableware, and other purposes. Because of their high-quality materials, they should only be recycled once, either due to hygiene reasons or for other reasons.

A PET pelletizing line works by applying a double-disc cooling system and washing process to clean the plastic flakes. Once the plastic flakes are cleaned and dried, they are extruded into pellets. These pellets can be used to make new PET plastic products. A double-disc cooling system ensures a low IV (increasingly low-grade PET) material is evenly mixed. In addition, the pelletizing line uses a German Siemens PLC control system.

EPS

The EPS pelletizing line is a modern manufacturing process used for processing EPS foam. Its main parts are an extruder, skjar skipti, viftu afhendingu, eftirlitskerfi, and a filter. The EPS pelletizing line can treat various kinds of EPS foam, including plastic, paper, and foam. It is also known as a woodern tilfellum.

EPS PS

An EPS PS pelletizing line is a process that produces foamed products from a mixture of polystyrene micro-pellets. Unlike the conventional EPS beads, these foamed products are made using the same routes. The pelletizing line involves three stages: pre-foaming, ageing, and molding. The production line's capacity is up to a thousand kilograms per hour, depending on the specifications.

The main components of an EPS PS pelletizing line are: a hard-surface gear reducer, water cooling circulation system, special material barrel, screw, and ring. The control system is comprised of Siemens PLC, Omron, Schneider, and other famous brands. These machines feature high-quality, easy-to-operate controls. The EPS PS pelletizing line is easy to operate, thanks to the Siemens PLC and HMI.

PP PE

A PP PE Film/Bags Pelletizing Line is an innovative plastic recycling machine. It combines advanced recycling technologies with the actual application conditions to produce high-quality plastic pellets. These pellets are suitable for recycling various types of plastic, such as plastic bags, packing films, agricultural film, and many others. The plastic pellets produced by a PP PE Pelletizing Line can be used in a variety of industries, including building materials, drainage pipes, and plastic board.

The PP PE pelletizing line is connected to an extruder, screen changer, and Melt Pump. The water ring keeps the polymer from building up too much inventory between the extruder and die plate, which makes it possible to produce more consistent pellets. Moreover, the pelletizing line can benefit compounders, masterbatch, and reclaimers. The system's efficiency and reliability make it a reliable and cost-effective investment.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3