Contact us

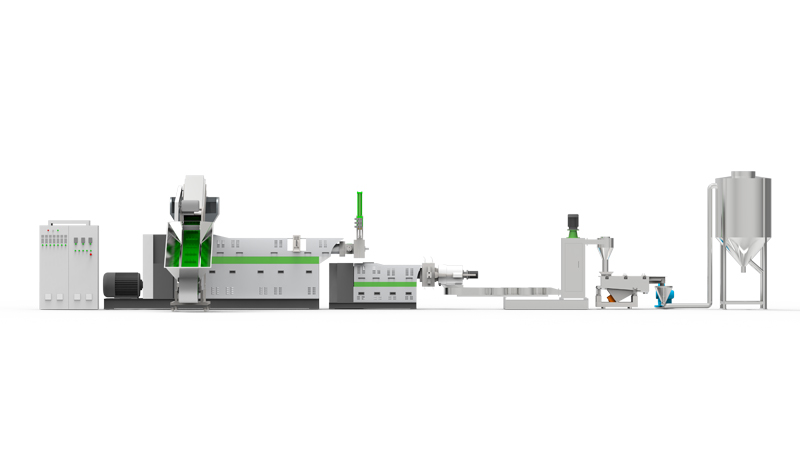

A plastic granulation line is a type of recyclin […]

A plastic granulation line is a type of recycling machine that is used to break down plastic products into smaller pieces. This process is done in order to make the material easier to recycle and to reduce its volume. These machines come in a variety of sizes and can be configured to handle a range of materials.

Common types of plastic granulators include open or solid rotors, staggered or segmented rotors, and soundproof models. Each type has its advantages and disadvantages. Generally, solid rotors are more effective for cutting heavy feedstocks while open rotors are better for less dense, airy materials.

The granulation process typically begins with a feeding system that removes any contaminants and then feeds the material into the plastic granulator. The granulator will then have a series of knives inside the rotor that cut the material into small chunks. These chunks will then be fed to other equipment such as an injection molding machine or a direct extrusion machine for further processing.

Choosing the right granulator is important for your operation’s success. It needs to be able to handle the material you are trying to process and it must also have the capacity necessary for your production demands. This requires a machine that can be cleaned and maintained on a regular basis to ensure your operation runs smoothly.

In addition to the material you are trying to granulate, other factors that affect your choice of plastic granulator include motor speed, cutting chamber size, and pelletizer type. Having these factors in mind will help you make the right decision. Motor Speed: The faster the motor, the faster the granulator can grind material. This is important because it can allow you to produce more output with the same amount of power, thus reducing your overall cost. Number of Knives: Typically, a granulator is equipped with 3-6 rotor knives and 2-3 bed or fixed knives. However, some granulators have up to 30 rotor knives.

Blades: The blades used in a plastic granulator are important for the strength of the granulation machine. They are typically made from stainless steel, but some models may use carbon fiber or titanium. This can be helpful for harder materials such as engineering or reinforced plastics.

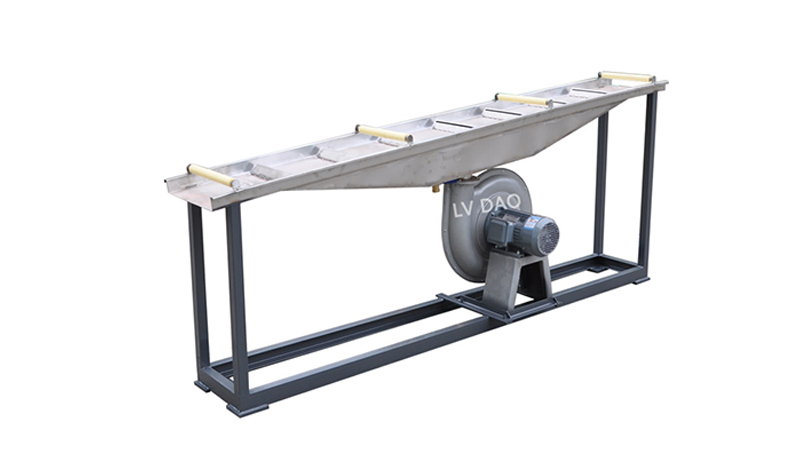

The granulator’s screen size is another important factor. A smaller screen will produce a lower output because it takes longer to process the material. In addition, the granulator’s design will determine how much product it can handle. This is especially true if the granulator will be operating with bottles or sheets. A granulator will need to be capable of a certain amount of material per hour. This can vary based on the type of material being processed, its dimensions, and whether it is being fed manually or with a conveyor system.

Other features of a granulator that will be useful in your operation include a hopper that is viewable, service accessibility, and the ability to change knives quickly. These features will help you make the best choices for your operation, as well as increase the reliability of your equipment.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3