Contact us

Depending on the product and formulation, a plas […]

Depending on the product and formulation, a plastic pelletizing line can produce between 100 and 500 kg of material per hour. The equipment in the line includes a granulator, a centrifugal cyclone, an automatic hopper, a storage bucket, and a vibrating distribution screen.

Each type of polymer has unique processing conditions and optimum set point temperatures. These features are important in choosing the right equipment for your process. Some compounds are extremely fragile and need special equipment, while others are difficult to machine and may require additional capacity. In addition, new products and additives may not work well with current equipment. A compounder should also make sure to choose a system that is easy to service and maintain, and allows for minimal waste of material.

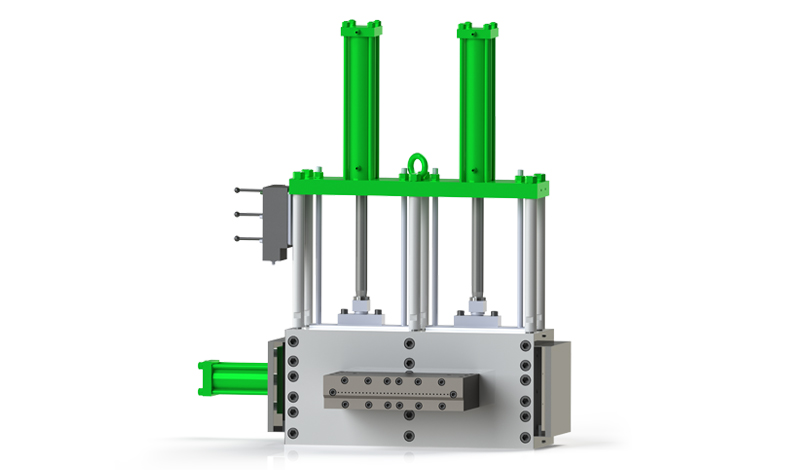

For most polymer compounding production, a strand die system is ideal. This pelletizing design is simple to operate and has convenient maintenance features. It is suitable for a wide range of polymer processes, including recycled materials. It is also suitable for manufacturing filled or amorphous polymers.

A twin screw extruder is a widely used process for plastic compounding, masterbatch making, and hard plastic recycling. It is also a popular choice for plastic compounding with additives, because it ensures a uniform mixture of polymers.The main extruders are 38CrMoAlA, wearable and smooth cutting.

The presence of fines in filler-filled compositions is a common problem, especially for amorphous polymers. For this reason, a pelletizing line must be able to produce consistent pellet sizes and shapes. The shape and size of a pellet are important in subsequent processing operations, as well.

In addition to ensuring consistency of shape, a compounder must also make sure that the pellet is free of voids and volatiles. To do this, it is a good idea to choose a machine that is designed with a fluid-heated die plate, which reduces the amount of heat that is lost. This results in more stable processing conditions and higher-quality products.

In addition to the basic strand pelletizing system, there are many specialized systems that can help to match the needs of a specific manufacturing process. For example, a water-ring plastic pelletizing line is specifically designed to recycle post-industrial and household plastics. It has a water circulating system, a hopper to store PVC pellets, and a blower and centrifugal dewatering unit.

While each pelletizing design is beneficial in different ways, a good approach is to combine the best technologies for each kind of material. This helps to create a more effective and efficient pelletizing strategy. It can also be useful to understand the pelletizing process and technology in order to find ways to improve it. The knowledge of how to optimize a pelletizing process can ultimately help a compounder to achieve maximum results.

In addition to deciding on a pelletizing design, a resin producer must also consider the number of products that will need to be processed. It is important to choose a line that is capable of producing a variety of products in a flexible and efficient manner.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3