Contact us

The complete supporting facilities of a Pelletting Line […]

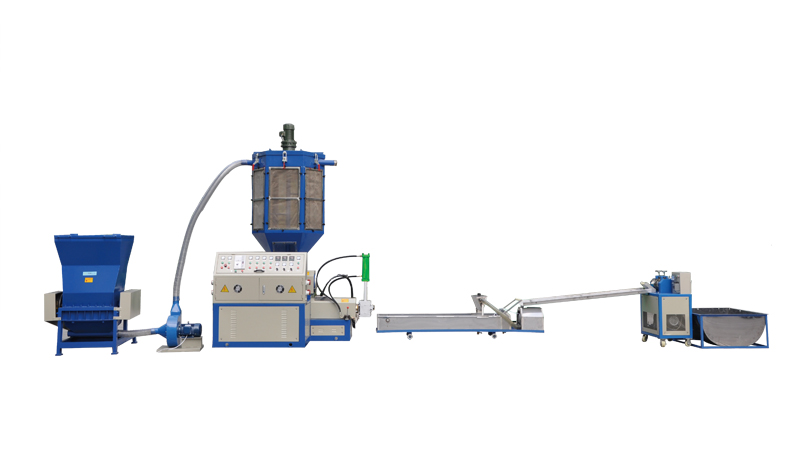

The complete supporting facilities of a Pelletting Line provide automatic continuous production and process various raw materials into granules. Its features include low power consumption and compact footprint, and its high quality finished products have various applications. This machine adopts split power distribution system to avoid overheating and ensures high product quality. A variety of plastics can be processed, including biodegradables, tyres, and tires.

Pelletizing lines come in different types, such as air-cooled, underwater, and water ring. They are used for waste film recycling. The pellets produced by these lines are more environmentally friendly. The electrical cabinet system is energy-efficient and can be customized for the specific needs of the company. There are various models for different applications. You can choose a suitable one according to your specifications and budget. The following features are required for a Pelleting Line.

The PVC pelletizing line is specifically designed for the recycling of waste plastic. It can process sheet flakes and PVC pipe flakes. The PVC pelletizing line is designed to recycle all kinds of plastics. It is also capable of processing waste film and a variety of other materials. A PP PE Film/Bags pelletizing line is suitable for recycling tyres, bags, and plastic pipes.

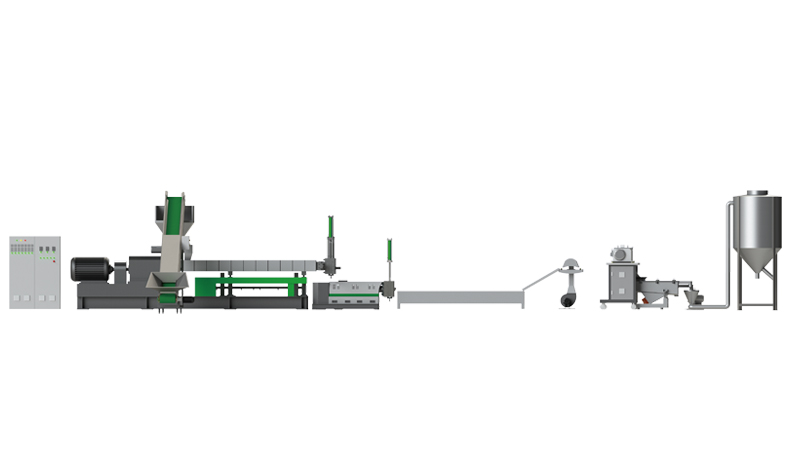

A Prism pelletizing line is a versatile solution for producing plastic and other materials. A PP PE Film/Bags Pelleting Line has many advantages, including a high efficiency and low operating cost. It can easily handle the waste film and plastics, and it is capable of recycling other plastics. This machine is available in several sizes, and can be customized to meet the needs of the customer.

A Pelleting line consists of a single screw extruder with 24 mm diameter and a 25:1 barrel ratio. A micro pellet system is also available. It produces pellets of excellent quality. This machine is widely used in plastic compounding and recycling. It is ideal for manufacturing plastics with a low carbon footprint. The Micro Pellet System has many benefits. It can produce a variety of profiles, ranging from PET to PLA.

A pelletizing line is comprised of two parts. The first part is the extruder. A second is the feed system, and feedstock is supplied through the feeder by the feed system. Both of these components work together to form the finished product. The Pelletizing line is an essential component of the entire facility, and it is not a difficult investment to install. The equipment is installed in a highly automated process with a fully automated feed system.

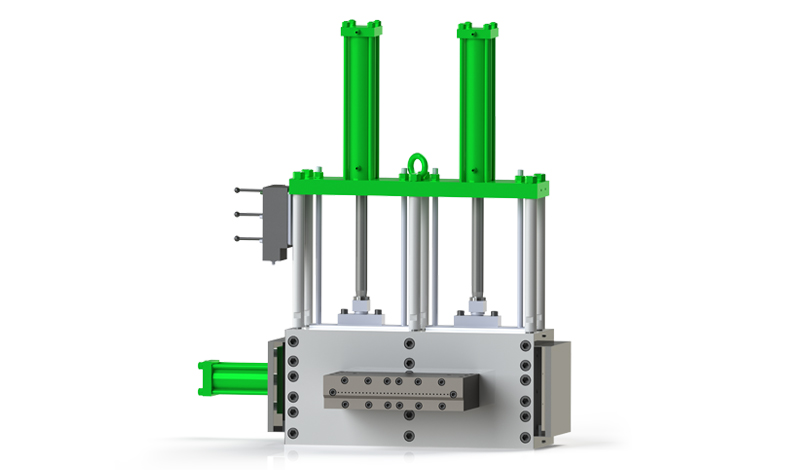

An extruder is an important part of a pelletizing line. The machine is a central piece of machinery, and it is a crucial piece of equipment. Besides the extruder, other components of a Pelleting line include conveyors, rotor blades, and a cooling system. The cooling water in the Pelleting Line helps in controlling the temperature of the materials.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3