Contact us

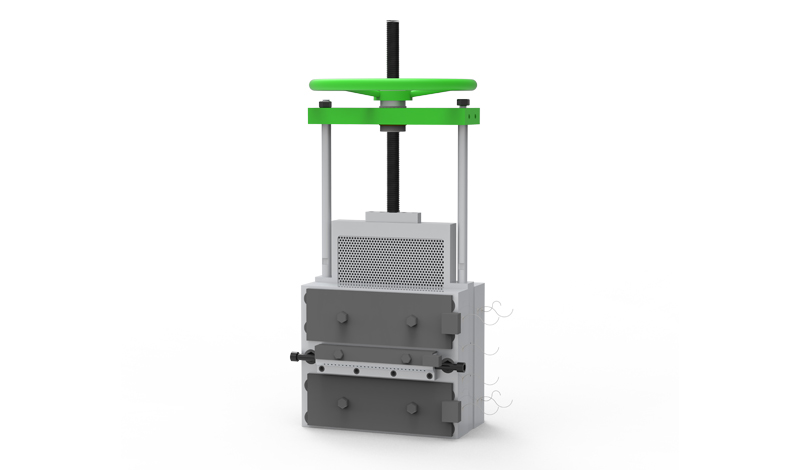

Plastic Granule Cutters contribute significantly to imp […]

Plastic Granule Cutters contribute significantly to improving the handling and storage of plastic materials, making them more manageable and efficient for various industries.

Reduction in Size and Volume

Plastic Granule Cutters are designed to reduce the size of plastic materials, including large components, sheets, and waste items, into smaller granules. This size reduction results in a significant reduction in the volume of the plastic material. Smaller granules are easier to handle, transport, and store compared to bulky plastic items in their original form. This compactness translates to efficient use of storage space.

Weight Reduction

Large plastic items can be heavy and cumbersome to handle, increasing the risk of workplace injuries during transportation and storage. Plastic Granule Cutters reduce the weight of plastic materials by breaking them down into smaller, lighter granules. This weight reduction not only improves safety but also simplifies material handling processes, making it easier for workers to manage plastic materials.

Enhanced Stackability

Granulated plastic materials have a more consistent and uniform shape compared to irregularly shaped plastic items. This uniformity allows for better stackability when storing the granules. Plastic granules can be neatly stacked in bins, containers, or pallets, optimizing storage space and reducing the chances of damage during storage.

Improved Transportability

Smaller, granulated plastic materials are easier to transport, whether within a facility or across longer distances. The reduced size and weight of granules make them suitable for various transportation methods, including conveyor belts, forklifts, and trucks. This streamlines the logistics of moving plastic materials between manufacturing stages or shipping them to different locations.

Customizable Granule Sizes

Plastic Granule Cutters offer flexibility in determining the size of the granules produced. Manufacturers can adjust the cutter settings to achieve specific granule sizes that best suit their storage and handling needs. Customization ensures that the granules are tailored to the requirements of a particular industry or application, further enhancing efficiency in handling and storage.

Simplified Packaging

Granulated plastic materials often require less packaging compared to large plastic items. This reduction in packaging materials contributes to cost savings and environmental benefits. It also simplifies the packaging process, reducing the time and resources needed for packaging plastic materials for storage or shipment.

Prevention of Material Distortion

Some plastic materials, particularly thermoplastics, can be susceptible to distortion or deformation when subjected to heat or pressure during storage. By converting these materials into granules, Plastic Granule Cutters minimize the risk of material distortion, ensuring that the plastic remains in its desired form and quality until it is ready for use.

Inventory Management

Granulated plastic materials are easier to inventory and track compared to large, irregularly shaped items. Businesses can maintain more accurate records of their plastic inventory, which is crucial for just-in-time manufacturing and minimizing excess stock. This improved inventory management leads to cost savings and efficient resource allocation.

Reduced Material Waste

Plastic Granule Cutters are highly efficient at converting plastic waste into granules. This means that less plastic material goes to waste, and more of it can be used effectively in manufacturing processes. This reduction in material waste not only conserves resources but also reduces disposal costs.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3