Contact us

Plastic Granule Cutters play a critical role in enhanci […]

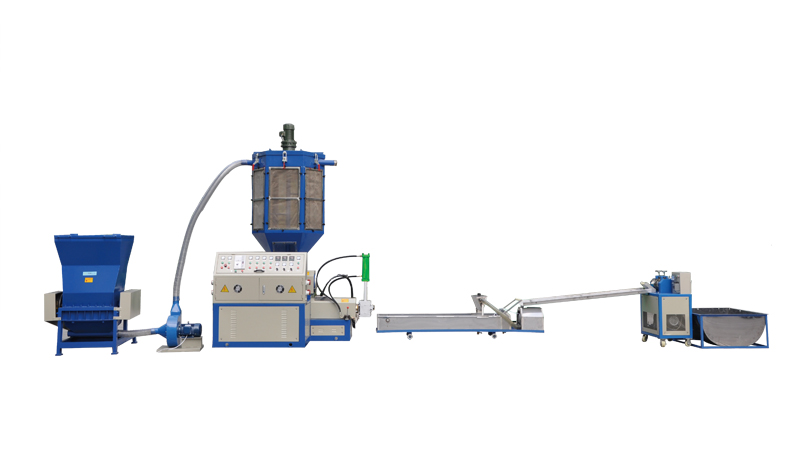

Plastic Granule Cutters play a critical role in enhancing recycling processes for plastic materials. They contribute to making recycling more efficient, cost-effective, and environmentally sustainable.

Size Reduction for Efficient Sorting

Large and bulky plastic items can be challenging to process and sort at recycling facilities. Plastic Granule Cutters are used to break down these oversized items into smaller, more manageable granules. This size reduction not only makes it easier to handle the materials but also facilitates the sorting process. Smaller pieces are more likely to pass through sorting equipment accurately, leading to improved separation of different plastic types and reducing contamination in recycling streams.

Consistent Feedstock for Recycling

Recycling facilities require consistent feedstock to operate efficiently. Plastic Granule Cutters provide a reliable source of uniformly sized plastic granules. This uniformity ensures that the recycling machinery can process the materials consistently, reducing downtime and maintenance. Moreover, consistent feedstock leads to higher-quality recycled products, as variations in particle size can affect the quality of the end product.

Versatility in Material Handling

Plastic Granule Cutters are versatile and can handle a wide range of plastic materials, including rigid plastics like PVC and HDPE, as well as flexible plastics like LDPE and PET. This versatility allows recycling facilities to process various types of plastic waste, making the recycling process more inclusive and effective. It also helps reduce the need for separate equipment for different plastic types, which can be costly and space-intensive.

Reduction in Transportation Costs

Large plastic items can be expensive to transport from collection points to recycling facilities due to their size and weight. Plastic Granule Cutters significantly reduce the volume and weight of plastic waste by converting it into granules. This reduction in transportation costs benefits recycling programs by lowering overall operational expenses and reducing the carbon footprint associated with transportation.

Energy Efficiency in Recycling

The recycling of plastic materials consumes less energy when using recycled plastic granules compared to producing new plastic from virgin materials. Plastic Granule Cutters contribute to energy savings by efficiently preparing recycled materials for further processing. This energy-efficient approach aligns with sustainability goals and reduces the environmental impact of plastic recycling.

Reduction in Contamination

Contamination of recycling streams with non-recyclable materials, such as metals, glass, or other types of plastic, can be a significant issue in recycling facilities. Plastic Granule Cutters help reduce contamination by breaking down plastic items into granules while leaving non-recyclable materials intact. This separation at the source enhances the purity of the recycled plastic stream, making it more valuable and marketable.

Lower Recycling Costs

Efficient recycling processes can lead to cost savings. Plastic Granule Cutters contribute to lower recycling costs by streamlining material preparation, reducing sorting complexity, minimizing contamination-related expenses, and optimizing the recycling workflow. These cost savings can make recycling programs more economically viable and attractive to both businesses and municipalities.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3