Contact us

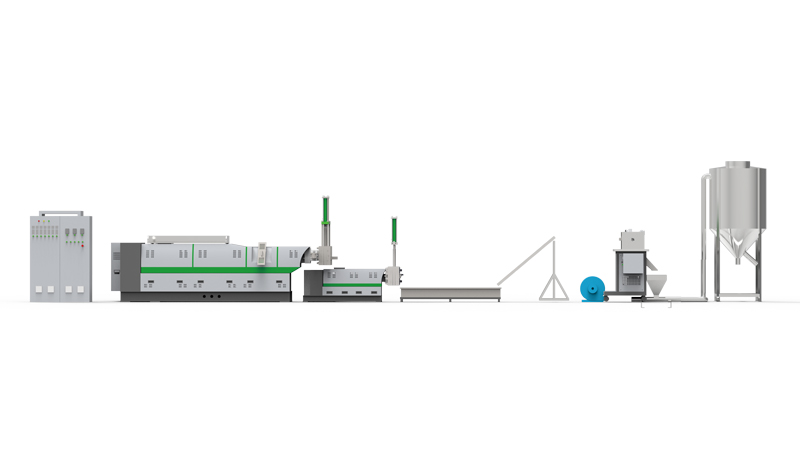

The black spot problem of plastic granulator in the gra […]

The black spot problem of plastic granulator in the granulation process is a common failure phenomenon, especially for colored and light-colored products, often in the final large-scale production process.

In order to avoid the harm of carbonization to plastic products as much as possible, the key is to effectively prevent and minimize the loss. In order to deeply understand the nature of carbonization, we must also be good at using effective solutions. We need to strictly control every aspect of solving and preventing carbonization of plastic products.

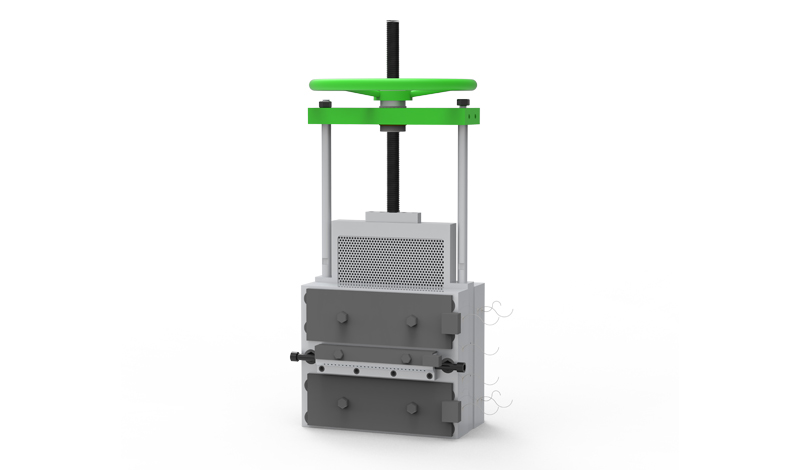

ldf film manual feeding granulator

In the actual production of plastic products, the feeding port is generally isolated before the plastic recycling machine is shut down, the plastic melt in the extruder and the head is removed, the temperature of each zone is turned off, and then the power is turned off. Due to the strong adhesion of the plastic melt to the metal, it is impossible to completely eliminate it every time the machine is shut down. In the end, there will always be a thin layer of plastic melt firmly adhered to the barrel and the machine of the extruder. On the inner wall of the head and the screw, the equipment stays in a high temperature state for a long time during the natural cooling and cooling process after shutdown and the next heating process, and obvious thermal deterioration occurs, gradually turning yellow and zooming into carbides. According to the conventional shutdown method, effective sealing measures are not taken at both ends of the die opening and the feed opening of the machine head, which causes the air to enter the machine to produce oxidation, which promotes the thermal deterioration of the residual plastic in the machine, and provides favorable conditions for carbonization.

To quickly clean the carbide in the machine, it is necessary to use a harder plastic or its return material to clean with white mineral oil, and the temperature should be appropriately increased by 10~15°C. At this time, the plasticizing ability of the small extruder should be considered. For large and medium-sized extruders that can plasticize ultra-high molecular weight plastics, they can be cleaned with ultra-high molecular weight plastics or their return materials and white mineral oil. Because the hardness of ultra-high molecular weight plastics is better, and when the temperature is high, the cleaning object will be softened, so that it becomes easy to fall off, which is beneficial to the carbides being carried out by the plastic melt. During the cleaning process, the rotation speed of the extruder is repeatedly switched between low speed and high speed several times. If there is still room for the motor load, the extruder can be stopped and restarted repeatedly during operation to further improve the cleaning effect. When the carbides (black spots) in the melt are significantly reduced, replace the usual plastic and clean it until it is clean, and gradually adjust to the appropriate temperature, then normal production can be performed.

Since the equipment is a metal structure, its thermal expansion rate is quite different from that of plastic, and the adhesion of carbonized plastic to metal is reduced. In the body, there are many black spots on the inner and outer walls of the product, and many quality problems such as perforation or leakage are prone to occur. Quality requirements, these black spots are the carbides after thermal deterioration of the residual plastic in the machine. Usually, the machine is washed by continuous extrusion of plastic to exclude the plastic melt with black spots, and the washing time is as long as 3-5 hours. If the original ultra-high molecular weight plastic cup is carbonized and the original color products are produced, it will greatly increase the difficulty of washing the machine, make the washing machine longer and the washing cost higher.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3