Contact us

As plastic waste continues to be a major environmental […]

As plastic waste continues to be a major environmental concern, recycling plastics has become increasingly important. One key tool in the recycling process is the plastic crusher. In this article, we’ll explore how to recycle plastics the right way with a plastic crusher.

Step 1: Sort Your Plastics

The first step in recycling plastics is sorting them. Plastics can be classified into seven different types, each with unique properties that determine how they should be processed. The easiest way to identify the type of plastic is to look for the resin identification code, which is typically found on the bottom of plastic containers. Once you have sorted your plastics by type, you can move on to the next step.

Step 2: Prepare the Plastics for Crushing

Before using a plastic crusher, it’s important to properly prepare the plastics. This means removing any metal or other non-plastic materials that may be attached to the plastic. You should also make sure the plastics are free of any food or other contaminants that could interfere with the recycling process.

Step 3: Choose the Right Plastic Crusher

There are a variety of plastic crushers available on the market, each with different features and capabilities. When selecting a plastic crusher, consider factors such as the types of plastics you will be processing, the volume of plastics you will be recycling, and your budget. It’s important to choose a crusher that is powerful enough to handle your recycling needs without overloading or damaging the machine.

Step 4: Operate the Plastic Crusher Safely

Before operating the plastic crusher, be sure to read and follow the manufacturer's instructions for safe use. This may include wearing protective gear, such as gloves and goggles, and ensuring that the plastic crusher is properly grounded to avoid electrical hazards. Always operate the machine at the recommended speed and avoid overloading it with too much plastic at once.

Step 5: Store and Transport the Crushed Plastic

Once the plastics have been crushed, they can be stored or transported for further processing. It’s important to properly label and store the crushed plastics according to their resin type to ensure they can be properly recycled. Consider using reusable containers or bags to transport the plastics, as this can help reduce waste and minimize environmental impact.

In conclusion, recycling plastics the right way with a plastic crusher requires proper sorting, preparation, and operation of the machine. By following these steps, you can help reduce plastic waste and contribute to a more sustainable future.

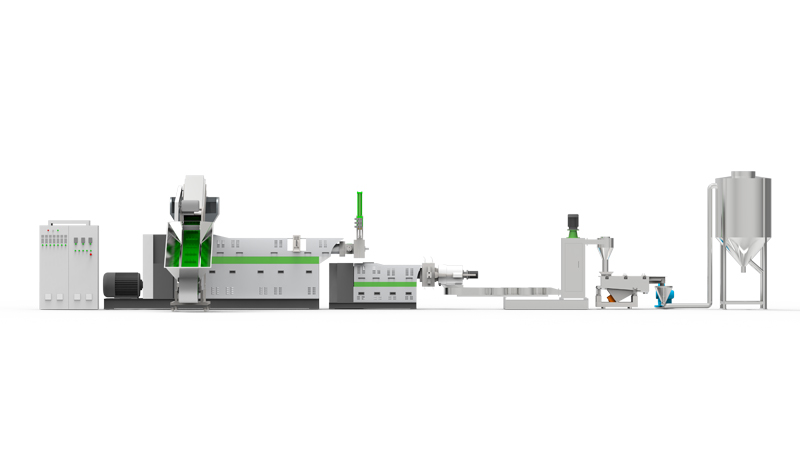

1.The film crusher is used for crushing film,bottle and so on.The blade material is 6CR2SI.It can be add realizing automatic-feeding ,high degree of automation.

2.It adopts revolving claw-shaped blade and combined blades, the stress is equally pressed, which makes the machine stable and makes little noise. It is very easy to change the mesh, and is efficiency and energy saving.

3.Specially designed hopper with curtains to prevent material flybacks. Integrated rundown safety device prevents access to the rotor until it has come to a complete stop. A safety switch prevent machine startup when the front panel is open and the machine features emergency stop buttons on the machine body and control panel.

4.The base frame has a solid welded construction with anti-vibration rubber feet to reduce vibration and noise.' The drive motor is mounted on tension rails to allow easy adjustment of the V-belt tension. Integrated suction trough for material discharge.

6.The film crusher has three models, each with different output, power, shape size.The minimum output is 250kg/h and the maximum output is 600kg/h.It can be customized according to their desired output, power, mesh.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3