Contact us

The granulator adopts a special screw design and differ […]

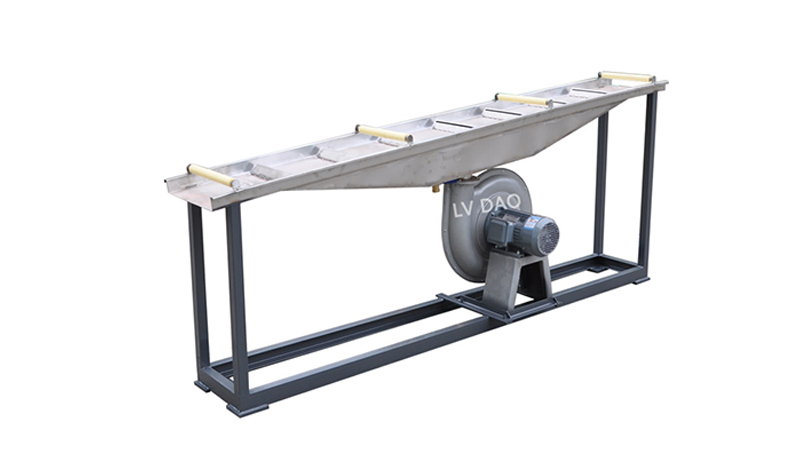

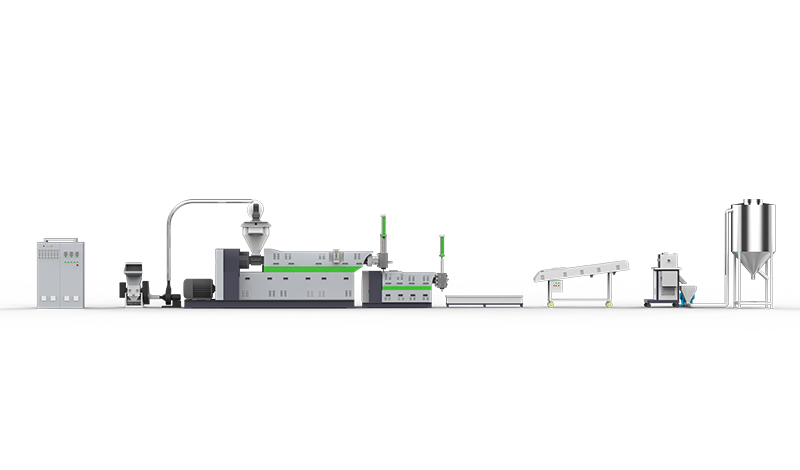

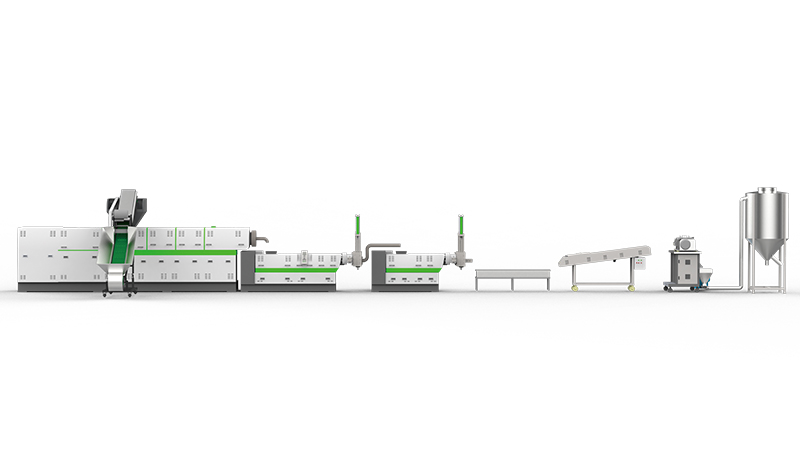

The granulator adopts a special screw design and different configurations, which is suitable for the production of PP, PE, PS, ABS, PA, PVC, PC, POM, EVA, LCP, PET, PMMA and other plastics for recycling and color mixing granulation. The gearbox adopts a high-torque design to achieve noise-free and stable operation. The screw and barrel are specially hardened, which are wear-resistant, good mixing performance, and high-yield. The design of vacuum exhaust or ordinary exhaust port can drain away moisture and exhaust gas during the production process, so that the material can be discharged. It is more stable, and the rubber particles are stronger, which guarantees the excellent quality of the product.

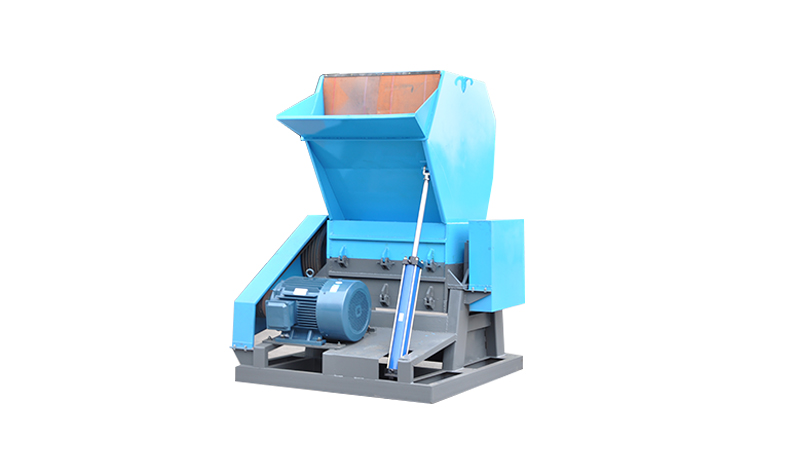

Plastic granulator is mainly used for processing waste plastic film (industrial packaging film, agricultural film, greenhouse film, beer bag, handbag, etc.), woven bag, agricultural convenient bag, basin, barrel, beverage bottle, furniture, daily necessities, etc. It is suitable for most common waste plastics. It is a plastic recycling processing machine that is widely used and widely used in the waste plastic recycling industry and is popular with users.

The main component of the plastic granulator is the plastic extruder, which is composed of an extrusion device, a transmission device and a heating and cooling device. Extrusion includes screw, barrel, hopper, head and die.

In the processing process, with the help of auxiliary machinery, the plastic scraps are added to the extruder, and the plastic is heated by heating equipment to melt. The screw in the extruder moves under the drive of the reducer to remove the melted plastic from the base of the barrel. , Partially filtered and wire-drawn through the head to achieve the purpose of regeneration.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3