Contact us

During plastic recycling process, plastics are separate […]

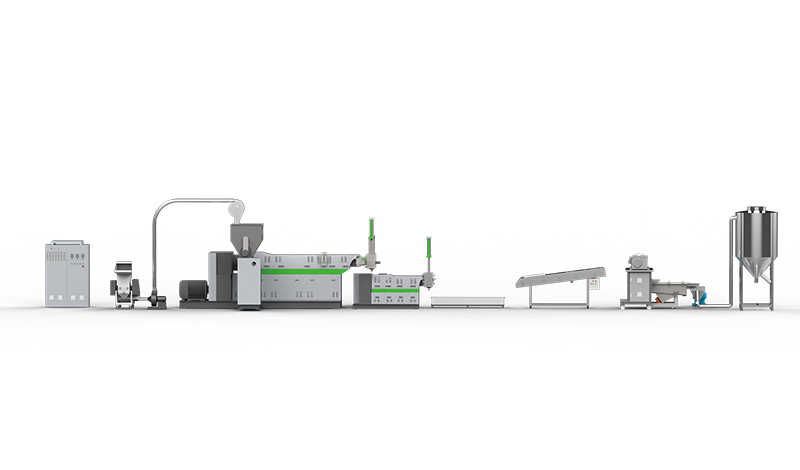

During plastic recycling process, plastics are separated into fragments. Waste plastics need to be washed in order to remove any impurities. This is done by a plastic washing recycling machine. This machine is designed with high automation, and offers a great output. The machine comes with an LCD screen panel and an emergency pause option. It also has a high output capacity. It is suitable for plastic waste, and can be configured in different workshop layouts.

The plastic washing recycling machine can be designed according to the different types of contaminant. For example, if you want to recycle LDPE/LLDPE film, the machine can be designed with a specific feeding system. Another machine is able to separate high density plastics from low density plastics. The machine can also remove water. The machine is suitable for a wide range of plastic materials, and can be used to process agricultural films, package films, and greenhouse films. It can also process plastic waste into pellets.

The plastic washing recycling machine is designed to maximize its revenue. The machine also comes with an emergency pause option, and can be used to wash a variety of plastic materials. The machine is designed with a computer-controlled side-feed screw feeder. This feeder automatically feeds the materials into the extruder. This machine is suitable for plastic scraps, plastic films, and plastic bags. The machine can be configured in an S shape or in an L shape. The machine is manufactured from stainless steel SUS 304.

The machine has a high output capacity and is suitable for a wide range of plastic materials. The machine is also equipped with a high volume hot air blower. This blower can be used to recirculate the hot air for re-use. It can save a lot of energy. The machine is also highly efficient. It can be used for recycling LDPE/LLDPE film, polyethylene film, and other plastic scraps.

The machine is suitable for washing PP PE films/bags, and can be configured as an L shape, an S shape, or an S+U shape. The machine is designed with high automation, and is equipped with an LCD screen panel and an emergency pause option. It also has a high output capacity. The machine is suitable for plastic scraps, and can be configured in a wide range of workshop layouts. The machine is designed with a computer-controlled side-feed screw feeder. This feeder automatically feeds the materials into the extruder. This machine is suitable for plastic scraps, and can be configured in a wide range of workshop layouts. The machine is manufactured from stainless steel SUS 304.

The machine is designed to separate waste hard plastic from dirty hard plastic. It is suitable for various waste plastics, and can be used to separate clean Waste Hard Plastics from dirty Waste Hard Plastics. The machine is designed with a high capacity and low energy consumption. It is able to work automatically for 3-4 people. The machine is designed with a high speed separator, and is able to remove dirt from the plastic.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3