Contact us

A plastic granulation line is a device that processes p […]

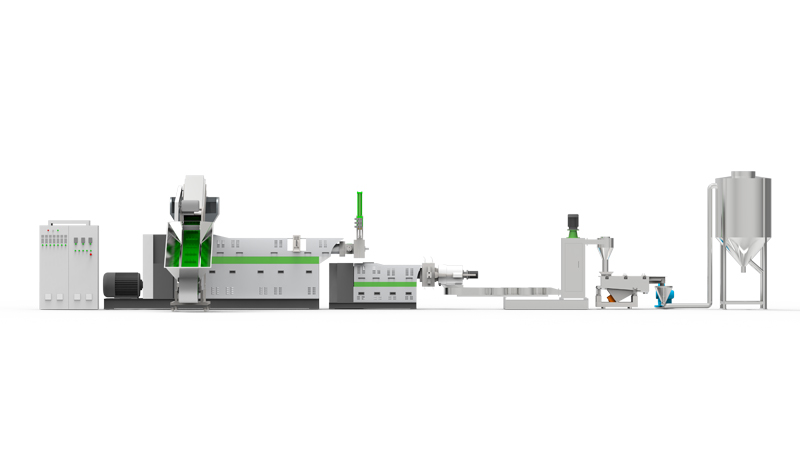

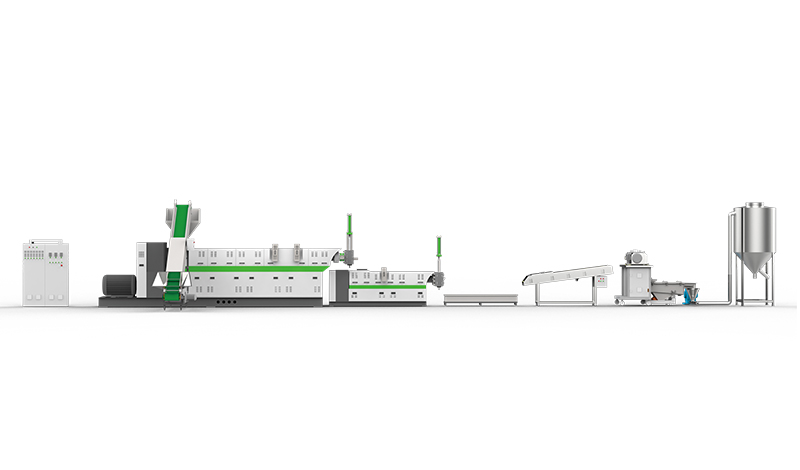

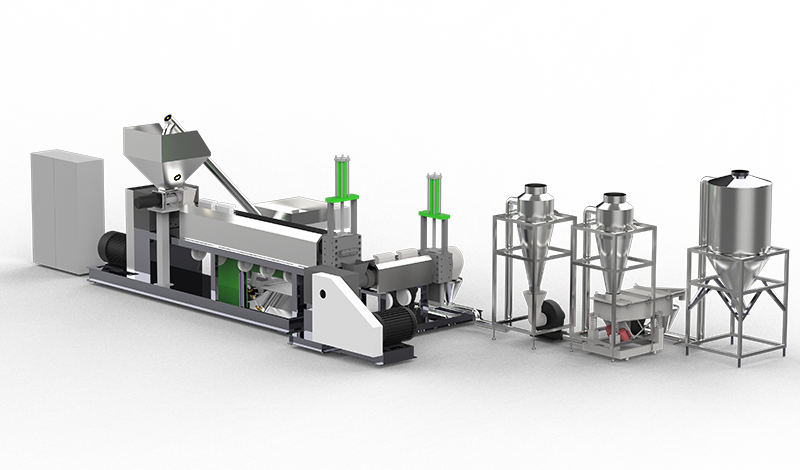

A plastic granulation line is a device that processes plastic wastes. It processes polyethylene, polypropylene, polystyrene, and fluf. It also recycles LDPE and HDPE film scraps. Typically, this equipment processes 40 to 50 kg of film per hour.

This type of plastic granulator uses a linear vibrating screen with a vibrating motor to throw up the pellets. These pellets are sorted, cleared, and sometimes loaded into the loading bunker of an extruder. The machine is designed to be durable and can operate around the clock. In addition, it has a low energy consumption, a simple structure, and is suitable for assembly line operation.

Plastic pelletizing machines usually include an extruder, a heating and cooling system, and auxiliary machines. These machines are used to form pellets that can be used for a variety of applications. The main section of a plastic pelletizing machine is the extruder, which combines an extruder, transmission system, and heating and cooling system. The extruder system then uses pressure to form a continuous extrusion die.

One of the most expensive parts of a plastic granulation machine is the electric motor. Because of this, many suppliers choose to use substandard motors to cut costs. However, this does not necessarily translate into superior results. A better motor will produce the best crushing efficiency. For this reason, Wiscon Envirotech recommends using second-grade motors to reduce power consumption and lower operating costs.

Plastic pelletizing is a relatively new form of recycling. It involves converting plastic waste into pellets that are similar to cereal flakes. The granulated plastics must be cleaned before they can be used. This is due to the fact that they may contain contaminants like stones, glue, paper, and food. In addition to cleaning, these pellets must also be cut into pellets and pneumatically transferred to storage silos or big bag filling stations.

The first machine in a plastic recycling granulation line is the plastic crusher. It can crush plastic film into tiny pieces and clean them at the same time. The blade on the plastic crusher is sharp and has a closed sealing design. It is also very safe, as its blade cuts through plastic film into tiny pieces in a very short amount of time. The second machine is the Shuliy plastic dewatering machine, which uses strong centrifugal force to dewater plastic.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3