Contact us

Plastic pollution has become one of the most pressing e […]

Plastic pollution has become one of the most pressing environmental challenges of our time. The abundance of single-use plastic products and improper disposal methods have led to a significant increase in plastic waste in landfills and oceans, causing severe harm to ecosystems and human health. Recycling has emerged as a crucial solution to mitigate the negative impact of plastic waste on the planet. To maximize recycling efforts, the granule cutter has emerged as a powerful tool in the recycling industry.

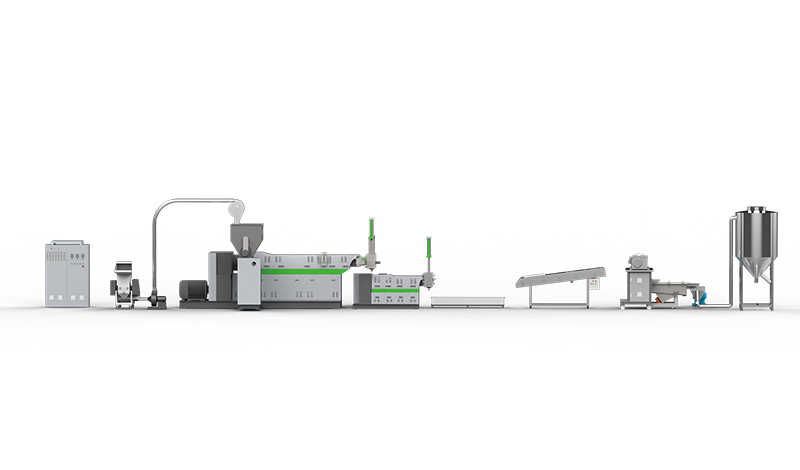

The granule cutter is a cutting-edge machine designed to transform plastic waste into high-quality granules that can be used in the production of new plastic products. It offers a range of benefits that significantly enhance the efficiency and effectiveness of plastic recycling processes. Let's explore how this innovative technology can revolutionize your plastic recycling efforts.

Enhanced Processing Capacity:

The plastic granule cutter is equipped with advanced cutting mechanisms that enable it to process a large volume of plastic waste in a relatively short amount of time. This increased processing capacity allows recycling facilities to handle higher quantities of plastic waste, leading to improved recycling rates and reduced reliance on landfills.

Superior Granule Quality:

One of the primary goals of plastic recycling is to produce high-quality granules that can be used as raw material for new plastic products. The granule cutter ensures superior granule quality by precisely cutting plastic waste into consistent sizes. This uniformity enhances the properties of the granules, making them suitable for a wide range of applications in various industries.

Versatility in Material Handling:

The granule cutter is designed to process different types of plastic waste, including rigid plastics, films, bottles, and more. Its versatility allows recycling facilities to handle a diverse range of plastic materials, expanding the scope of their recycling operations. With the granule cutter, a wider range of plastic waste can be transformed into valuable granules, reducing the need for virgin plastic production.

Waste Reduction and Cost Savings:

By transforming plastic waste into granules, the granule cutter plays a vital role in waste reduction. Recycling facilities can minimize the amount of plastic waste sent to landfills or incineration facilities, contributing to a cleaner and healthier environment. Moreover, utilizing recycled plastic granules in manufacturing processes can lead to cost savings for businesses, as recycled materials are often more cost-effective than virgin plastics.

Environmental Benefits:

The granule cutter directly addresses the environmental impact of plastic waste by promoting a circular economy. By recycling plastic and converting it into granules, this technology reduces the extraction of natural resources required for virgin plastic production. It also reduces energy consumption and greenhouse gas emissions associated with plastic manufacturing processes. Embracing the granule cutter in plastic recycling efforts contributes to a more sustainable future and a healthier planet.

Promoting a Circular Economy:

The granule cutter is an essential tool in creating a circular economy for plastics. By transforming plastic waste into granules, it enables the reuse of materials and reduces reliance on new plastic production. This shift toward a circular economy promotes a sustainable approach to plastic consumption, where plastic waste is seen as a valuable resource rather than a disposable item.

In conclusion, the granule cutter is a powerful technology that maximizes plastic recycling efforts. Its enhanced processing capacity, superior granule quality, versatility in material handling, waste reduction, and environmental benefits make it an invaluable asset in the recycling industry. By incorporating this cutting-edge machine into plastic recycling processes, we can take significant strides towards mitigating plastic pollution and building a more sustainable future.

VERTICAL CUTTER FPB-G-80-200 CAPACITY:100-450KG/H

Suitable for granulating after extrude, fracture surface smooth,especially easy to clean blade for colorful granules.

Yuyao Lvdao Plastic and Rubber Machinery Co., Ltd is well known Vertical cutter FPB-G-80-200 Capacity:100-450kg/h manufacturers and industrial Vertical cutter FPB-G-80-200 Capacity:100-450kg/h suppliers in China. We can make the products following the customers' requirements,like the shape,size,color,logo and other spec details. According to the different characteristics of various plastic materials to develop a batch of new products, maximize to meet the needs of customers.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3