Contact us

Plastic mixer machines have become an indispensable par […]

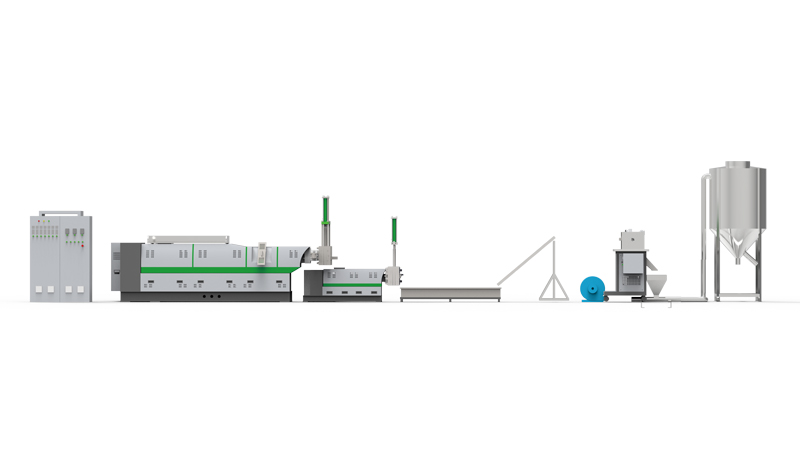

Plastic mixer machines have become an indispensable part of the manufacturing industry. These machines are used to mix plastic materials to produce a variety of products. They are commonly used in the production of plastic products such as pipes, films, bags, and bottles, among others. Plastic mixer machines come in various sizes and capacities, and they are designed to cater to the specific needs of different manufacturing processes.

A state-of-the-art plastic mixer machine can significantly improve the efficiency and productivity of a manufacturing process. This is because these machines are equipped with advanced features and technologies that ensure the production of high-quality plastic products in a timely and cost-effective manner. In this article, we will explore how a state-of-the-art plastic mixer machine can help maximize efficiency and productivity in a manufacturing process.

Automation

A state-of-the-art plastic mixer machine is equipped with advanced automation features that make it easier to operate and control. This means that the machine can run continuously for long periods, reducing the need for manual intervention. Automation also reduces the likelihood of errors and improves the accuracy of the mixing process. This results in a more efficient and productive manufacturing process.

Versatility

A state-of-the-art plastic mixer machine is designed to handle a wide range of plastic materials. This means that it can be used to produce a variety of products, depending on the needs of the manufacturing process. This versatility eliminates the need for multiple machines, which can save space and reduce costs. It also allows manufacturers to produce different products without having to invest in new equipment.

Speed

A state-of-the-art plastic mixer machine is designed to mix plastic materials quickly and efficiently. This means that the manufacturing process can be completed in a shorter time, which increases productivity. The speed of the mixer machine also ensures that the materials are mixed evenly, resulting in consistent product quality.

Energy Efficiency

A state-of-the-art plastic mixer machine is designed to be energy efficient. This means that it consumes less energy compared to older machines. This reduces the overall energy costs of the manufacturing process, resulting in significant savings over time. In addition, energy-efficient machines are also better for the environment, as they reduce carbon emissions.

Quality Control

A state-of-the-art plastic mixer machine is equipped with advanced sensors and controls that monitor the mixing process in real-time. This allows manufacturers to detect and correct any issues that may arise during the process. Quality control ensures that the final product is of high quality and meets the required standards. This reduces waste and increases customer satisfaction.

In conclusion, a state-of-the-art plastic mixer machine is a valuable asset for any manufacturing process that requires plastic mixing. It offers advanced features and technologies that maximize efficiency and productivity, while also ensuring high-quality products. By investing in a state-of-the-art plastic mixer machine, manufacturers can reduce costs, save time, and increase profits.

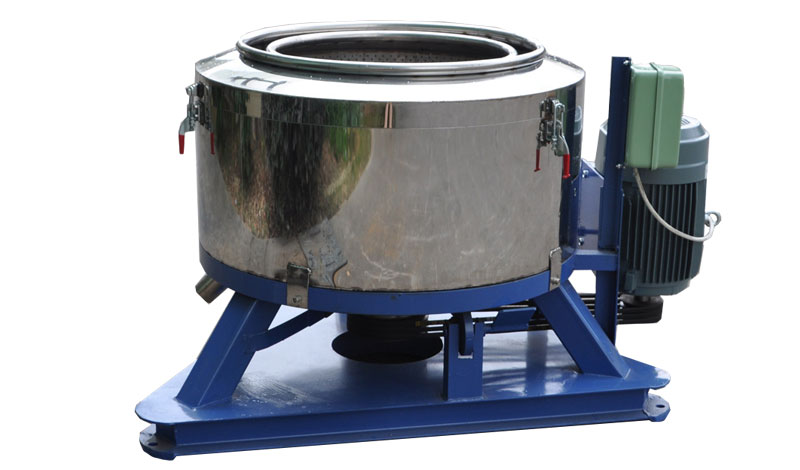

HORIZONTAL PLASTIC MIXER MACHINE

Suit for powder , flakes or pellets mixing. The barrel of LDW100-LDW300 can be rotated.

1.Horizontal mixer is widely used for mixing and stirring powder, flake, granule and special material in plastic, chemical and other industries.

2.Practical and compact, ensuring that the barrel capacity is larger than similar products at the same time, the overall height is greatly reduced than similar products

3.100-300kg bucket body adopts tilting bucket design, mixing bucket can be arbitrarily inclined in 0°-100°, for cleaning or discharging needs; Mixing time can be set automatically stop as needed; Safety protection device to ensure safe operation.

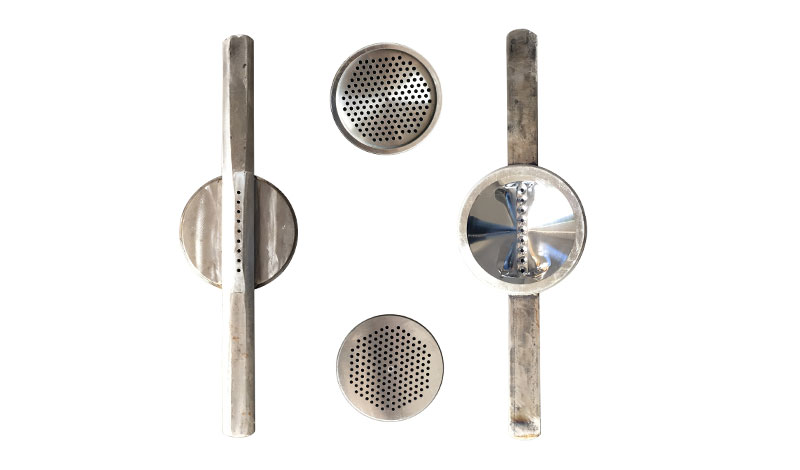

4.The barrel body and blade are made of stainless steel, often keeping clean and clean; The blades are made by a special process to make the mixing effect more incomparable to competitors, while also minimizing the energy loss;

5.Horizontal mixer has six models.Its maximum total volume is 1000kg,the minimum total volume is 100kg.The maximum power is 11kw,the minimum power is 2.2kw.The lower height greatly alleviates labor; It can be customized drying type horizontal mixer.

6.It is a new type of mixing equipment with high efficiency, high uniformity, high load factor,low energy consumption, low pollution and little destruction to frangible material.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3