Contact us

The world is facing a major environmental crisis due to […]

The world is facing a major environmental crisis due to the rampant use of single-use plastic, which results in tons of plastic waste that doesn't biodegrade for decades and pollutes our oceans, rivers, and landfills. This issue not only harms our planet but also poses a threat to the human population and wildlife. To tackle this problem, people worldwide are moving towards sustainable solutions, and one of them is the use of a plastic agglomerator.

A plastic agglomerator is a machine that converts waste plastic material into usable granules by heating and melting it. This approach is a significant step towards reducing plastic pollution because the waste plastic is not only collected and transported to a landfill but rather recycled and transformed into a useful material.

The plastic agglomerator process starts with feeding the waste plastic into the machine, where it is preheated and cut into small pieces to facilitate the melting process. The plastic is then heated and melted to a certain temperature, which is necessary to eliminate any contaminants, such as dirt, food residue, or other materials from the waste plastic. The agglomerated plastic is then transformed into small beads while inside the machine, which serves as a precursor to the final product. The granules produced can then be combined to make new products such as plastic bags, toys, and even furniture.

One of the significant advantages of using plastic agglomerators is their ability to recycle a variety of plastic products at once. It means that various types and forms of plastic waste, such as PVC, HDPE, LDPE, and PET can be recycled together. The flexibility that this affords means that more plastic waste can be recycled more efficiently, preventing waste from going into landfills and water bodies.

From the point of view of cost-effectiveness, plastic agglomerators are very efficient. They use a lesser amount of energy for heating and melting, making the process more cost-effective as compared to alternative methods, such as incineration.

Another critical benefit of using a plastic agglomerator is the positive impact it has on the environment. Since the produced material can be used to produce new products, the demand for new plastic production decreases. A decrease in the demand for new plastic decreases the demand for oil, since plastic is derived from oil. Reducing oil consumption lessens air pollution, limits climate change, and protects our environment. Furthermore, agglomerators equip plastic recyclers and processors and allow them to stop sending waste underground, into landfills, and move towards circular usage of materials.

Furthermore, using a plastic agglomerator is an efficient way of reducing the amount of plastic waste that ends up in landfills. It is a smart way of reducing the carbon footprint of plastic use, promoting environmental sustainability. The use of plastic agglomerators means that plastic waste is re-used and transformed into a new, valuable product. Moreover, it is an excellent method of turning plastic waste into something useful and preventing its pollution of the natural environment.

In conclusion, the use of plastic agglomerators is an effective way of turning waste into useful material. By using a range of plastic waste products, they reduce the demand for new production and oil consumption, leading to direct environmental benefits through lower carbon dioxide pollution rates. Additionally, this innovative solution helps protect our planet, preserves natural resources, reduces greenhouse gases, and, ultimately, improves our lives. The world needs more of this critical technology if we are to deal with the challenges of plastic waste and environmental degradation while pursuing sustainable development.

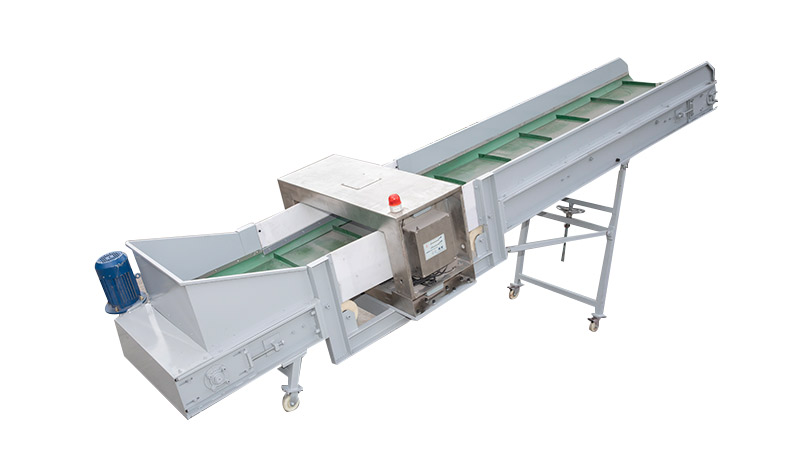

It is suitable for film recycling and granulating before processing.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3