Contact us

Plastic crusher: Five points for safe production of cru […]

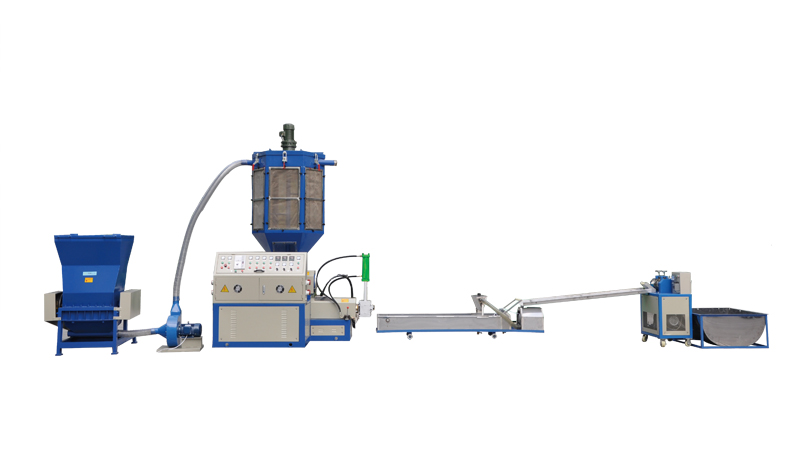

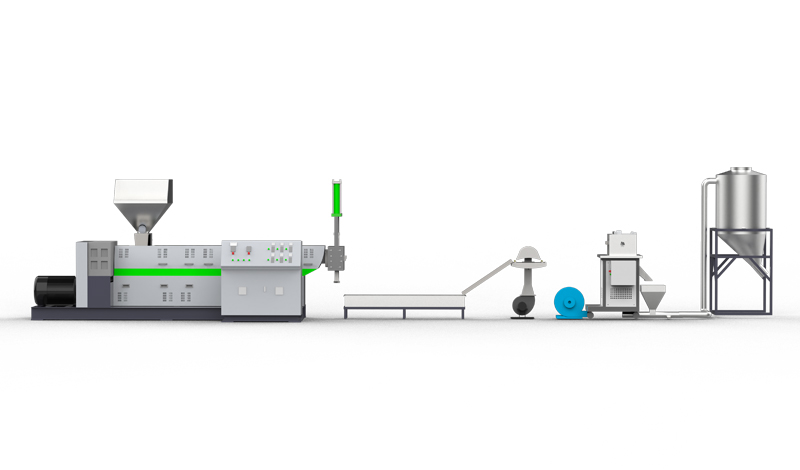

Plastic crusher: Five points for safe production of crusher To ensure that the crusher is in good operating condition, in addition to the usual maintenance and maintenance, it is the safe preparation work before the equipment starts.

1. We know that the lubrication system is the vascular circulation of a piece of equipment. Therefore, before starting, users should check whether the lubrication of the bearing is good, whether the contact of each part is good, and whether there is enough grease in the contact area.

2, check the sturdiness of the components before starting. If the crusher makes a noise and the components are misplaced after starting, can it be safe to produce? Therefore, it should be carefully checked. If looseness is found, tightening measures should be taken in time to tighten the screws and connecting parts.

3. For the safety of the operators, when starting the crusher, you must carefully check whether the protective devices, grounding protection and electrical equipment meet the requirements, and ensure that the operators have worn dust-proof glasses and masks to eliminate hidden dangers of insecurity and ensure that all kinds of The safety facilities must be completely free from defects.

4, the belt is an important part of the transmission device. If the belt slips, the equipment cannot be started. Therefore, check whether the transmission belt is installed correctly and in good condition. If the belt is damaged, it should be replaced in time. When there is oil on the belt or sheave, apply Wipe clean with a clean cloth in time.

5. It is recommended to carry out an empty car test run before feeding, and make sure that the crusher is normal before proceeding to production.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3