Contact us

Wasting plastic polypropylene plastic granulation line […]

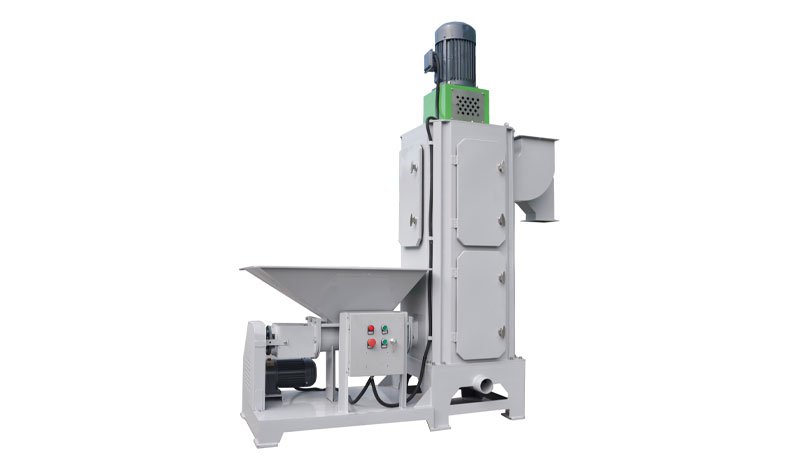

Wasting plastic polypropylene plastic granulation line is made up of: metal roll clamp, plastic conveyor belt, friction-balanced centrifugal machine, de-greasing tank, metal scoop, plastic lifting device, metal raking machine, water tank, vacuum pump, etc. The manufacture process of plastic granulation line for recycling includes several steps and follows a systematic procedure. Step one in the process involves preparing plastic granulation material for coating and molding. The plastic granulation material is generally low-density polyethylene (LDPE) that is molded into various shapes and forms. After the molding process is done, it goes to step two wherein it is sent to a roller or a brush that rolls it over a mandrel or a stack to form a smooth plastic slice.

Once the plastic granulation line for recycling is dried, it goes to the third and final step, which is washing. This washing process eliminates any residue or excess plastic material. The washing equipment for this process is generally a water washing machine with a high capacity suction wand, or a high pressure washing unit.

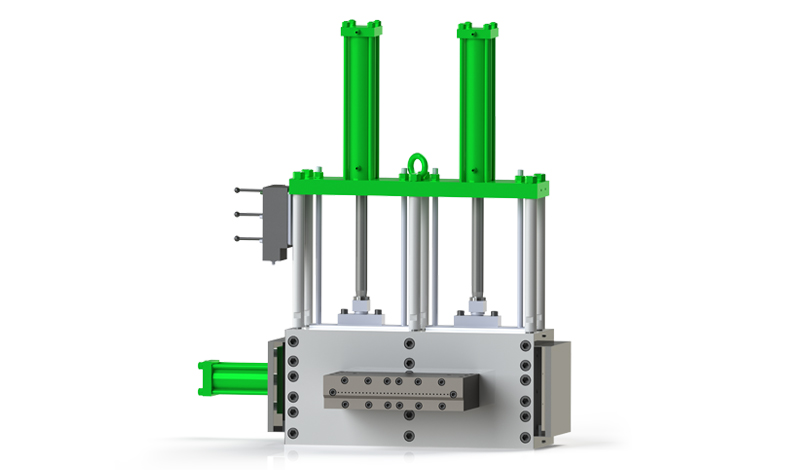

At this point, we are at the main machine generating the plastic granulation line for recycling, and this is a multi-stage machine that convert the plastic material to powder form, which is then sent to a grinding machine or a molding machine. This machine also called a converting machine can be either an electric or hydraulic type. This grinding machine can be used to make round or cylindrical products such as cans, caps, etc., as well as other plastic materials. However, there are some plastic material granulation machines that generate plastic pieces that fit like small particles or noodles.

View Plastic granulation line catalogue

After the plastic granulation line for recycling has been refined to the desired consistency, it is then sent to a milling or turning machine. At this point, the plastic material can be further processed into either nylon or polypropylene. The high speed mixer line then joins the two plastic materials together into the final product. Finally, this is packaged into either an empty can or a pre-labeled product.

Plastic granulation line for water pellets is a popular method in the removal of waste plastics. To use this type of plastic granulation line for water pellets, a water pelletizing machine is needed. While a standard water pelletizing machine works with standard plastics, the high speed plastic granulation line for water pellets requires special types of plastics.

Water can be very expensive and using plastic granulation line for recycling eliminates the need for storing water. A water pelletizing machine can be very costly to install, but since this is a much less expensive method than compacting or spinning, a smaller system would be more economical to install. Furthermore, the mixing and compacting process is much faster when using a water-based compacting system. This allows manufacturers to save a great deal of time and money on their manufacturing process.

With some brands of plastic water containers, manufacturers also offer a separate plastic washing system. The use of this system will often result in a higher water bill because the water will be used for cleaning the plastic containers instead of just washing them. To solve this problem, the plastic washing systems are sometimes included with the plastic granulation line for recycling. Plastic washing systems work very well because they can remove 99% of the small plastic flakes from the container without replacing the entire washing load. Therefore, this saves both the company that makes the container and the company that make the washing system money.

The CN-LVDAO plastic granulation process also reduces the need for washing lines. Washing lines are an extremely high-energy cost, but this process reduces the need for using the costly energy needed to operate the washing machines. Furthermore, plastic granulation reduces the need for the dangerous chemicals contained in laundry soaps. The addition of the pe washing line for recycling ensures that the company does not need to pay the high water bills that come with the disposal of these harmful chemicals.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3