Contact us

Plastic pellet machine manufacturers’ disposal of waste […]

Plastic pellet machine manufacturers’ disposal of waste plastics. When we clean at home, we may clean out some plastic bottles, but if they are discarded, they will pollute the environment. If they are piled at home, they will take up space. For this problem, plastic pellet machine manufacturers will Tell you this plastic is recyclable.

As long as there is a human’s place, there will be waste plastics, all kinds of waste plastics, such as packaging bags, woven bags, basins, barrels, plastic doors and windows, toys, appliance shells, beverage bottle industry waste plastic products, and plastic molding waste processing Wait, it's everywhere. Plastic raw materials are chemical products extracted from natural petroleum.

Petroleum is the lifeblood of modern industry and a non-renewable natural resource. Therefore, it is petroleum recycled plastic. Melt granulation uses waste plastics, and the contradiction between supply and demand of raw materials can alleviate the plastics, and the country can save a lot of foreign exchange for importing crude oil. Then let the professional personnel of the plastic pellet machine manufacturer guide us how to deal with it. In the natural environment, the plastic structure is stable, and the bacteria are not easily degraded by natural microorganisms. If it is not recycled, it will permanently exist in the environment and accumulate into pollutants. Great harm to the environment.

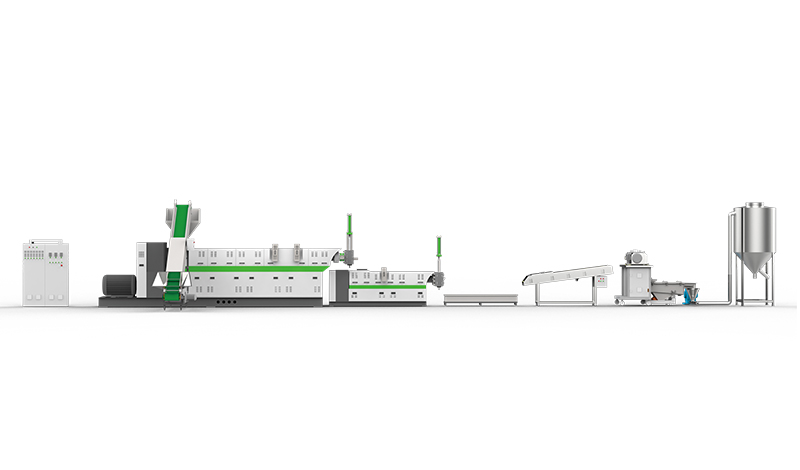

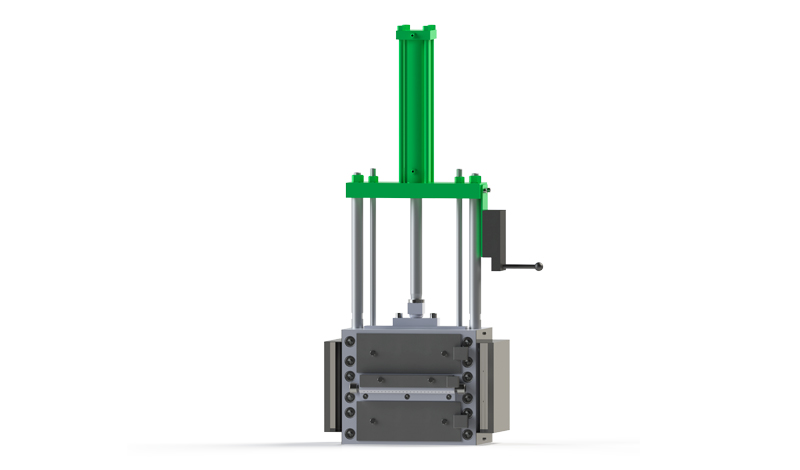

In normal times, what method do we use to deal with it? In real life, as long as it is a thermoplastic plastic, that is to say, a plastic that can be softened by heating to a certain temperature, such as a large number of industrial plastics, civilian plastics, packaging plastics, and electronic and electrical housings, almost all can be recycled. What kind of processes are involved in plastic recycling? Plastic pellet machine manufacturers simply say that there are two major processes-the first is pretreatment (that is, sorting, crushing, and cleaning) to become semi-finished products-and the second is granulation processing (that is, the semi-finished products are made into recycled particles). It can be used to make plastic products, such as plastic basins, plastic barrels, plastic tubes, non-woven fabrics, etc.-In addition, it can also be processed through deep and fine processing (that is, mixed, modified, and colored recycled plastics) Advanced processing to meet higher use requirements and maximize economic benefits)

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3