Contact us

Plastic pelletizing lines are an essential part of the […]

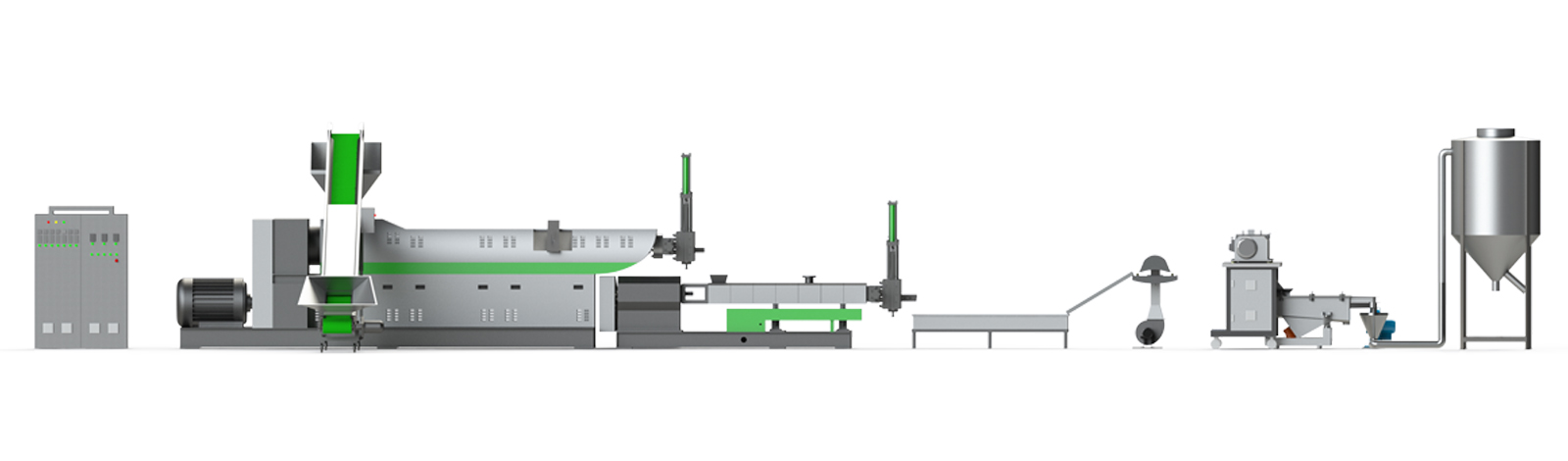

Plastic pelletizing lines are an essential part of the plastic manufacturing industry. They are used to transform raw plastic materials into small, uniform pellets that can be easily transported and used in a variety of applications. These lines are used by manufacturers of plastic products, as well as recycling facilities that process used plastic materials.

The process of plastic pelletizing begins with the collection and sorting of plastic waste. This waste is then shredded into small pieces and washed to remove any contaminants. Once the plastic is clean and free of impurities, it is fed into a pelletizing machine.

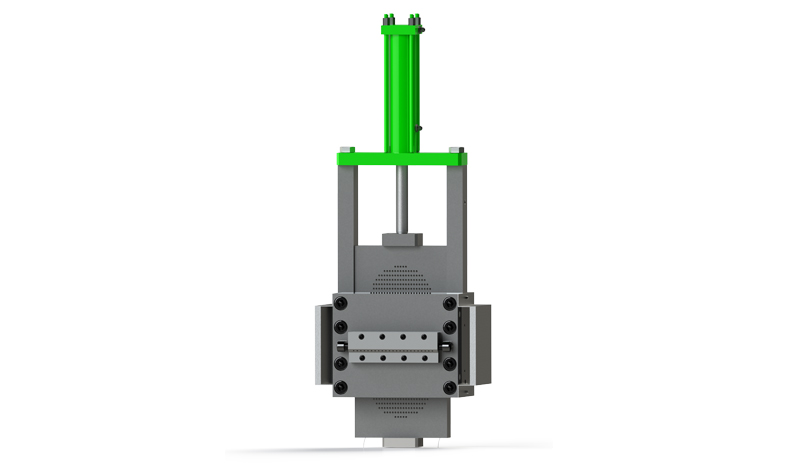

The machine works by heating the plastic material until it becomes molten. This molten plastic is then forced through a die, which creates small, cylindrical pellets. The pellets are cooled and solidified as they exit the die, and are then ready for use. One of the key benefits of plastic pelletizing is the ability to create uniform pellets of consistent size and shape. This is important for manufacturers who need to ensure that their products are of consistent quality. It also makes it easier to transport and store the pellets, as they can be stacked and stored in large quantities.

Another benefit of plastic pelletizing is that it allows for the recycling of plastic waste. By turning used plastic materials into new pellets, manufacturers can reduce their reliance on virgin plastic materials. This not only saves on costs but also helps to reduce the environmental impact of plastic production.

There are a variety of different types of plastic pelletizing lines available, each designed to handle different types of plastic materials and volumes of production. Some lines are designed for high-volume production, while others are better suited for small-scale operations.

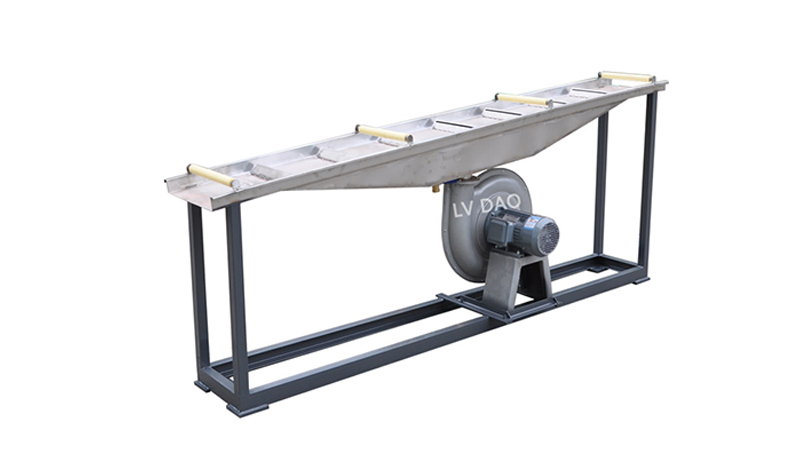

In addition to the basic pelletizing machine, many lines also include additional equipment such as shredders, washers, and conveyors. These additional components help to ensure that the plastic materials are properly prepared before entering the pelletizing machine and that the finished pellets are properly cooled and stored.

In conclusion, plastic pelletizing lines are a crucial component of the plastic manufacturing industry. They allow for the creation of uniform, high-quality plastic pellets that can be used in a variety of applications. Additionally, they play a key role in the recycling of plastic waste, helping to reduce the environmental impact of plastic production. With a range of different types of pelletizing lines available, manufacturers can choose the one that best meets their specific needs and production requirements.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3