Contact us

Plastic waste is a major environmental concern and its […]

Plastic waste is a major environmental concern and its accumulation in landfills and oceans poses a significant threat to the planet. As a result, there has been a growing demand for effective plastic recycling solutions. Revolutionizing the plastic recycling industry requires a combination of innovative technologies, effective policies, and public education campaigns. This article will focus on the equipment needed for plastic recycling, providing a comprehensive guide to the various types of equipment available and their uses.

1.Shredders

The first step in the plastic recycling process is shredding. Shredders are used to break down large plastic objects into smaller, more manageable pieces. Shredders can be categorized into different types based on their speed, blade configuration, and feed type. The two most common types of shredders are the single shaft and double shaft shredders. The single shaft shredders are used to shred light plastics such as PET bottles, while double shaft shredders are used for tougher plastics such as PVC pipes.

2.Granulators

After shredding, the plastic is reduced to small pieces called flakes. These flakes are further processed into granules or pellets, which are used as raw materials for manufacturing new products. Granulators are used to convert the flakes into small granules or pellets. The granules produced are of a uniform size and can be used in the production of new plastic products.

3.Washing Systems

Plastic waste is often contaminated with dirt, dust, and other impurities. Washing systems are used to remove these contaminants and ensure that the plastic is clean and ready for further processing. Washing systems can be divided into wet and dry systems. Wet washing systems use water and detergents to clean the plastic, while dry washing systems use air to remove dust and other impurities.

4.Drying Systems

After washing, the plastic must be dried before it can be further processed. Drying systems are used to remove any remaining moisture from the plastic. The most common types of drying systems are hot air dryers, centrifugal dryers, and vacuum dryers.

5.Separation Systems

Separation systems are used to separate different types of plastics from each other. This is important because different types of plastics cannot be processed together. Separation systems can be based on various technologies such as electrostatic separation, sink-float separation, and magnetic separation.

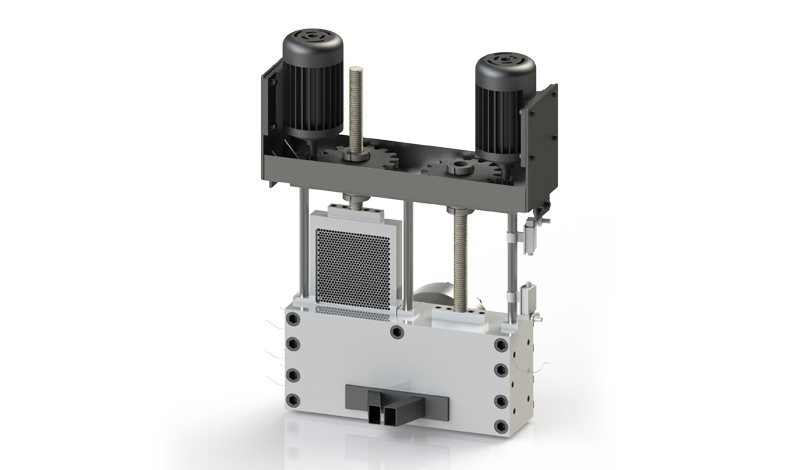

6.Extruders

Extruders are used to melt and form the plastic into different shapes. The most common type of extruder is the single-screw extruder. This type of extruder uses a single screw to melt and mix the plastic. The molten plastic is then pushed through a die to form a specific shape.

7.Injection Molding Machines

Injection molding machines are used to produce large quantities of plastic parts. The plastic is melted in the machine and then injected into a mold to form a specific shape. Injection molding is used in the production of a wide range of products such as toys, automobile parts, and electronic components.

In conclusion, the plastic recycling industry is rapidly evolving and adopting innovative technologies to tackle the plastic waste problem. The equipment mentioned above is essential for the plastic recycling process, and its proper selection and use can significantly improve the efficiency and quality of plastic recycling. However, it is essential to remember that equipment alone cannot solve the plastic waste problem. It requires a concerted effort from policymakers, businesses, and individuals to promote recycling, reduce waste, and adopt sustainable practices.

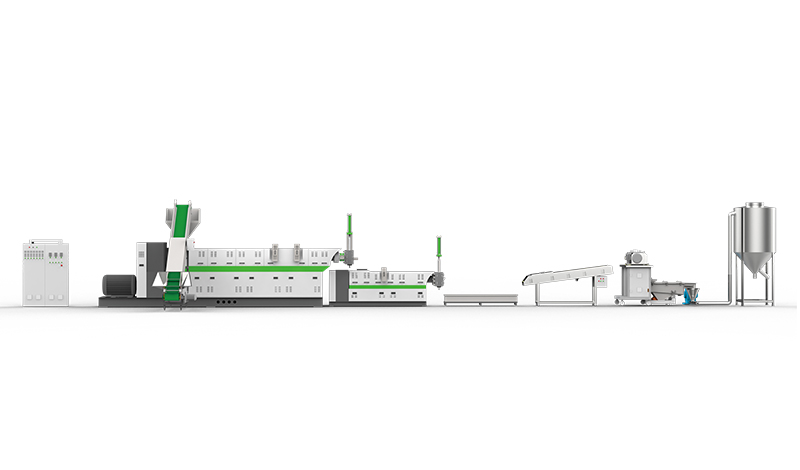

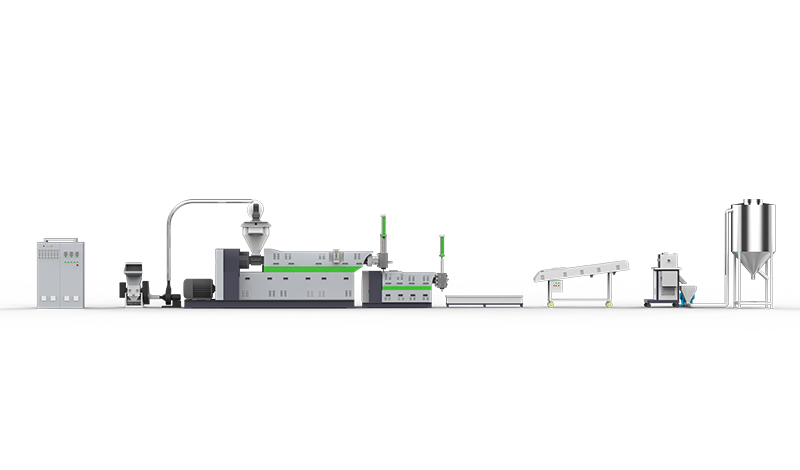

FILM FORCE FEEDING RECYCLING MACHINE LINE

1.film crushing--blower loading--force feeding--pelletizing system.

2.Easy operation,low cost and labor saving.

3.Provide water ring hot cutting,vacuum exhaust according to your requirement.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3