Contact us

Shear mixing is a fundamental process in plastic mixer […]

Shear mixing is a fundamental process in plastic mixer machines that plays a crucial role in achieving uniformity and homogeneity in plastic materials. It involves subjecting the materials to shear forces, which result in the deformation and alignment of polymer chains and the dispersion of additives, colorants, and fillers.

Understanding Shear Mixing

Shear Forces:

Shear forces are mechanical forces that act parallel to the surface of a material. In the context of plastic mixing, shear forces cause adjacent layers of material to slide past each other. These forces can be applied in various ways in plastic mixer machines, depending on the design and purpose of the mixer. Common methods of applying shear forces include:

Rotating Blades or Mixing Elements: Many plastic mixer machines are equipped with rotating blades, paddles, or other mixing elements. As these elements rotate, they create shear forces by pushing and pulling the material in different directions.

High-Speed Agitation: Some mixers utilize high-speed agitation or stirring to generate shear forces. The rapid movement of the mixing tool agitates the material, promoting shear and mixing.

Turbulent Flow: In certain mixer configurations, such as static mixers, turbulent flow can induce shear forces. When materials flow through these mixers, they experience turbulence, which leads to shear-induced mixing.

Role of Shear Mixing:

Shear mixing is employed in plastic mixer machines to achieve several important objectives:

Dispersing Additives: Shear forces help disperse additives, such as pigments, stabilizers, and flame retardants, evenly throughout the polymer matrix. This dispersion is essential for achieving the desired properties in the final plastic product.

Breaking Down Agglomerates: Agglomerates are clusters of particles that can form during the mixing process. Shear mixing helps break down these agglomerates, ensuring that the materials are uniformly distributed.

Aligning Polymer Chains: Shear forces align polymer chains in the material. This alignment enhances the material's mechanical properties, such as strength and stiffness, and can lead to improved performance characteristics.

Reducing Viscosity: In some cases, shear mixing can reduce the viscosity of the plastic material, making it easier to process. This is particularly important in extrusion and injection molding applications.

Homogenization: Shear mixing contributes to the overall homogenization of the material, ensuring that all components are thoroughly mixed and that there are no pockets of uneven composition.

Types of Shear Mixing in Plastic Mixer Machines

Shear mixing can take several forms in plastic mixer machines, depending on the design and configuration of the equipment. Here are some common types:

1. Batch Shear Mixing:

Blade Mixers: In batch shear mixing, blade mixers are commonly used. These mixers feature rotating blades that create shear forces as they move through the material. Blade mixers are suitable for small to medium-sized batches.

2. Continuous Shear Mixing:

Extruders: Extruders are an example of continuous shear mixers. They consist of a screw or an auger that conveys material through a heated barrel. The rotating screw generates shear forces as the material is pushed forward. Extruders are used in industries like plastic film production and compounding.

3. Planetary Shear Mixing:

Planetary Mixers: Planetary mixers utilize a unique mixing action where the mixing element revolves around its own axis while orbiting a central mixing bowl. This dual motion generates intense shear forces and is suitable for applications that require precision mixing, such as pharmaceuticals and cosmetics.

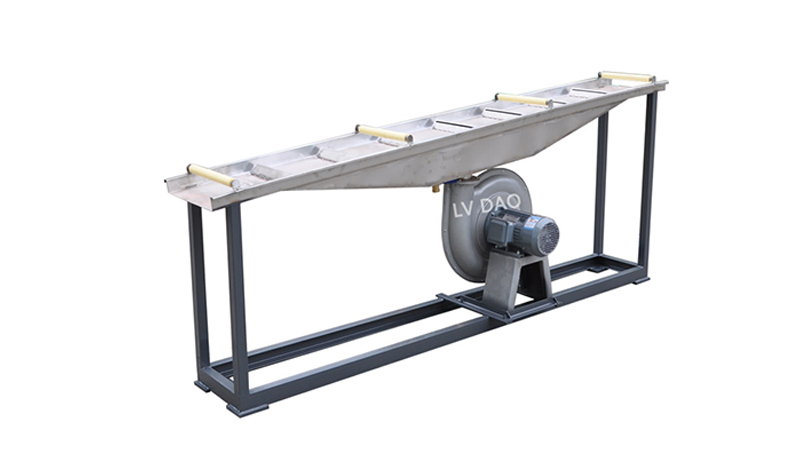

Low Speed Coloring and Mixing Machine

1.Designed with four-wheel vertical type,which is small in size and convenient for moving.

2.No over-temperature protection, overload protection, multiple safety protection.Dual digital display directly measured temperature and design temperature.Helical circular mixture,material can be mixed evenly within short period of time with high efficiency and low energy consumption.The timer may be chosen within 0-30 minutes for mixing.

3.Start automatically delay the opening of the electric power off automatic delay off the fan.Touch the light control automatically start a key.configure the exhaust filter to reduce pressure loss to prevent dust flying to protect the factory environment.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3