Contact us

Using plastic granulation technology, waste plas […]

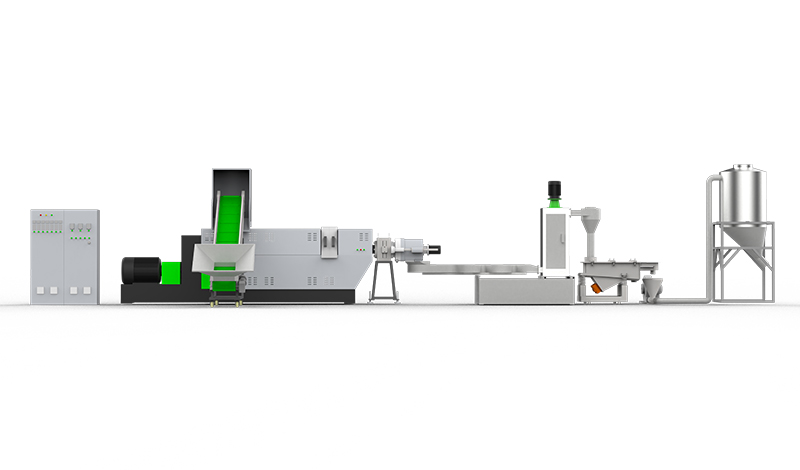

Using plastic granulation technology, waste plastic is recycled into recyclable materials. This process is a good way to reduce pollution, because it avoids incineration. In addition, this process also has economic benefits. It can reduce the cost of recycling by creating new plastic products, like plastic granules, foamed products, and biodegradable plastics.

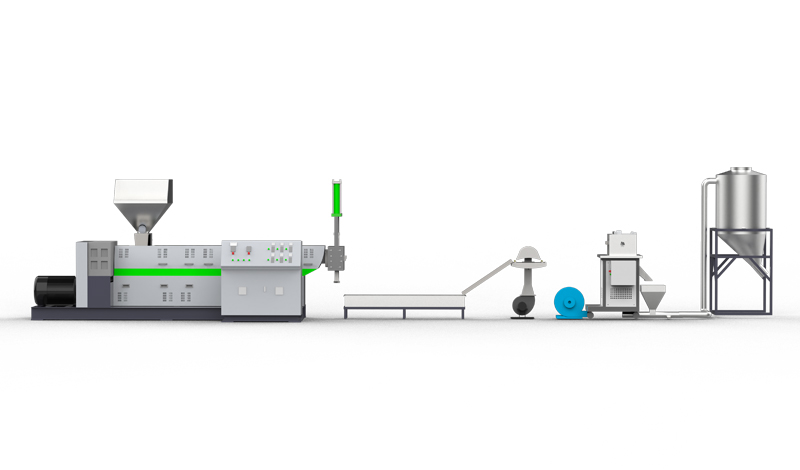

The process starts when the raw materials arrive on the granulation line. They are sorted, cleaned, and dewatered. After cleaning, they are processed and cut into smaller pieces. This is done with the help of an extruder. The material is then cooled to harden it for cutting. It is then cut into pellets. The pellets are then stored in storage bins.

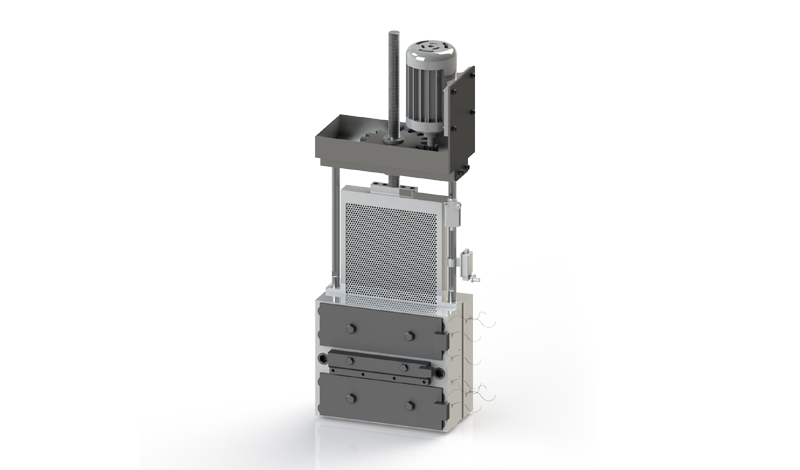

The granulator is a crucial piece of equipment on a plastic granulation line. The granulator is a machine that breaks down plastic scrap into smaller pieces. There are many granulators on the market, but all have common characteristics. The type of granulator you use depends on the size of your facility and labor requirements. It should be efficient and safe. Typically, it comes with a hopper and a cut-off device. Some granulators also have auto-rewind options.

There are two types of granulators, under press and hot-cutting. Under-press granulators are located below the trim station. They are used for sizing the finished product. This type of granulator has a die that is formed under pressure during the process. A few granulators have hardened cassette knives to ensure even portioning of the granules.

The main machine screw barrel of the granulator has been upgraded to better handle the feed acceleration. The barrel is made of imported high-quality steel. The barrel has a cone-like shape and is capable of producing a steady temperature. The barrel can also be adjusted to improve the plasticization of the granules. The speed of the screw is another variable that can affect the plasticization.

The type of material is also a factor in choosing a granulator. For instance, it is easier to granulate consumer plastics, since they are usually easier to break down. It is important to buy a granulator that is suitable for the plastics you plan to recycle.

A plastic granulation line includes a rinsing tank, a plastic crushing and washing machine, and a pelletizing machine. This equipment is used to recycle PET, polyethylene, and polypropylene. It is ideal for small to medium-sized plastic recycling plants. It can also be used to recycle woven bags, plastic food packaging bags, and other plastics.

The granulator can be equipped with a viewing hole and occasional purges. It is also equipped with multiple feed steams and calibration metering devices. Some granulators have hardened cassette knives and auto-rewind options. These granulators have the capacity to work at 240 degrees Celsius. They are also portable. They are easy to install and operate. They require only a few people to work. They are hooked up to local power sources.

The granulating line is the most important piece of equipment in the recycling process. It can convert plastic scrap into small, lightweight granules. These granules can be used for many different applications, including stones processing, food processing, and even glue.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3