Contact us

When you recycle plastic, you break it down into smalle […]

When you recycle plastic, you break it down into smaller pieces that can be reprocessed. The smaller pieces can be sold as raw material or used as additives in asphalt. The process also allows for the removal of impurities, including metal contaminants. Once sorted by colour and density, the plastic is ready to be recycled. During this process, the plastic waste is then mixed with supercritical water to make it as clean as possible.

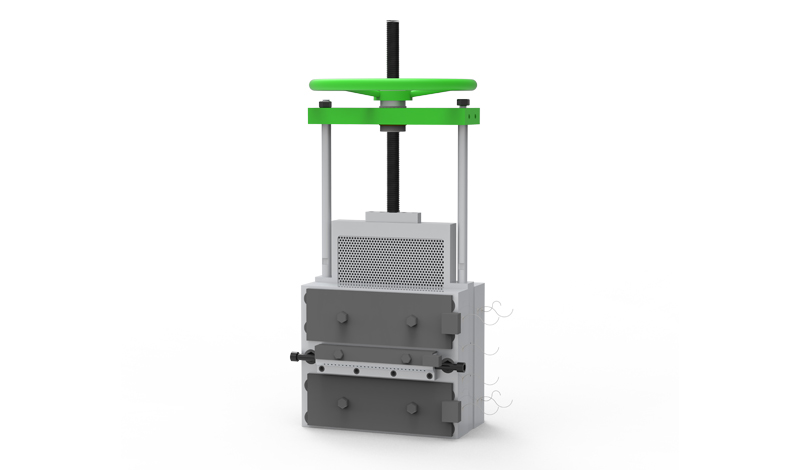

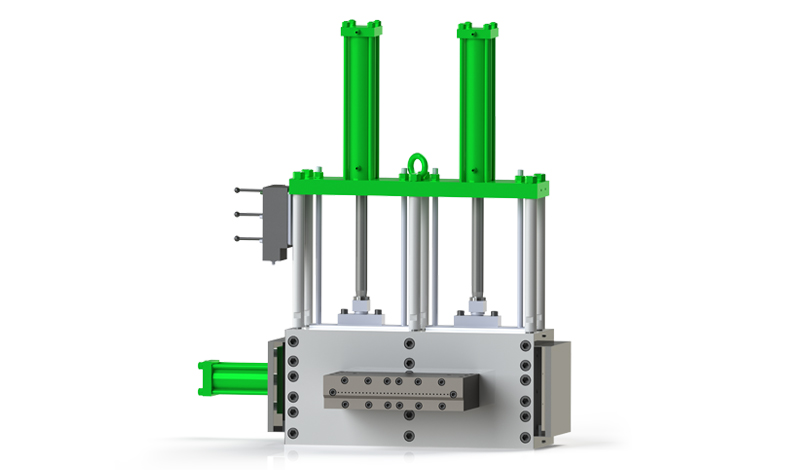

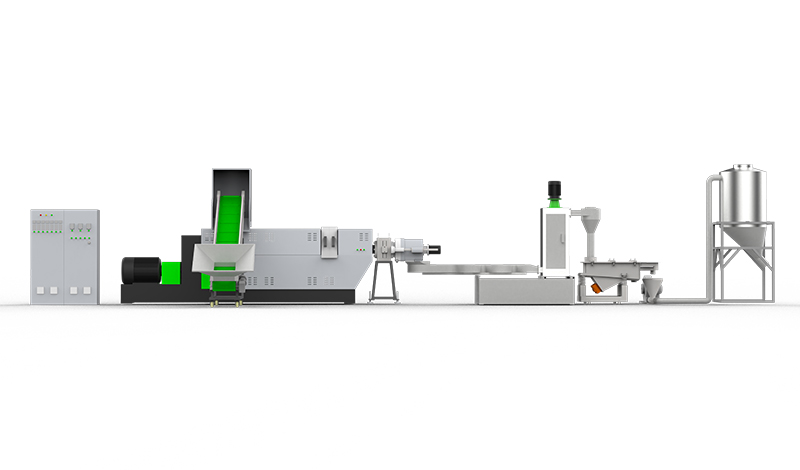

The machine's design and construction should be in accordance with industry norms and specifications. The production rate of the machine should be 100, 150, or 200 kg/hr. The efficiency of the machine can be determined by considering several parameters, including throughput and energy consumption. This machine is suitable for processing polyethylene and PET plastic waste. It is also useful in recovering byproducts and scraps from the plastic fabrication process. The machine should be robust enough to withstand the rigors of the plastic recycling process.

The cost of a plastic recycling machine should be low enough for a farmer to purchase. It should be easy to operate and maintain and be affordable for local entrepreneurs. The plastic recycling machine should be able to recycle different types of plastic and shapes. It should be made of readily available materials and reduce labour input. It should also have a higher capacity than manual operations. This way, it can reduce the amount of plastic products and labour used. It can also reduce the environmental impact.

In the near future, the demand for plastic recycling machines is expected to increase. The industry will be driven by high-tech innovation and environmental awareness. With a steady increase in the use of the machines, it is likely to expand. In the next few years, the plastic recycling machine market will witness a substantial growth. If you are considering purchasing a plastic recycling machine, make sure you check out our global directory of suppliers. You will definitely find a good deal.

The recycling process consists of melting plastics, shredding them, and processing them into granulates. This process can be made more efficient through continual innovation in recycling technologies. A reliable detector enhances the automatic sorting process. And closed loop recycling processes have also led to higher value applications for recycled plastic. PET sheets are up to 70% recycled. So, if you want to reduce your overall production costs, invest in a plastic recycling machine that has a top-notch energy efficiency.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3