Contact us

Plastic waste has become a major concern for the enviro […]

Plastic waste has become a major concern for the environment and the sustainability of manufacturing processes. Traditional manufacturing methods have often been associated with excessive waste, leading to the depletion of natural resources and the degradation of ecosystems. As a result, there has been a growing demand for more sustainable manufacturing solutions.

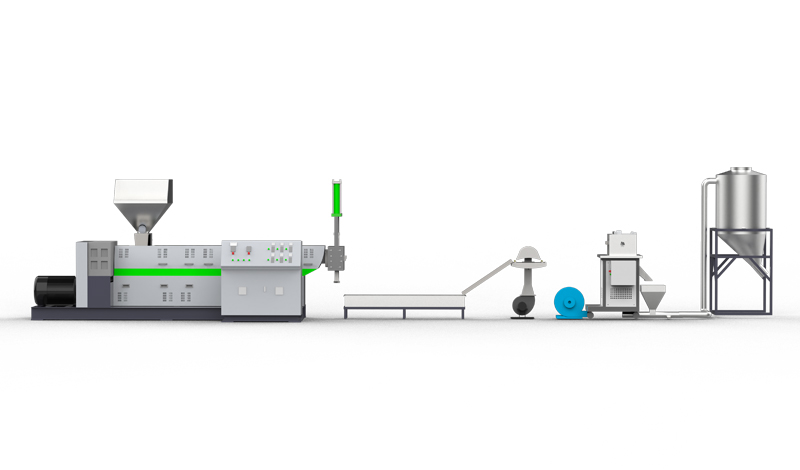

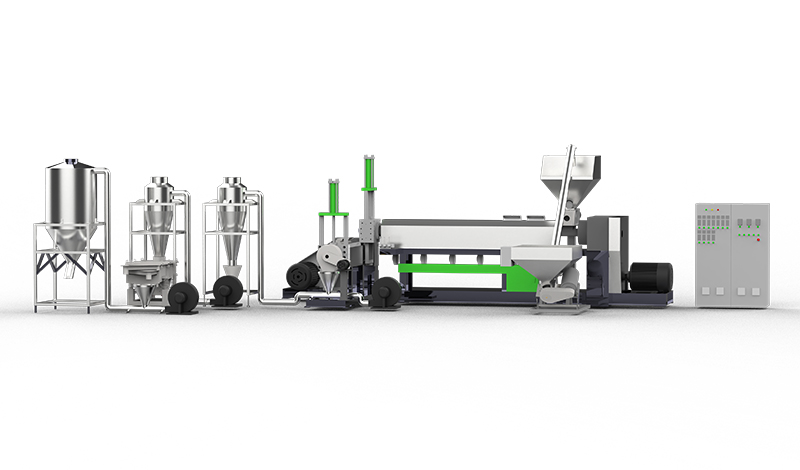

One such solution is the plastic granule cutter, a cutting-edge technology that is revolutionizing the plastic industry. This innovative machine is designed to recycle plastic waste by converting it into small granules, which can then be used as raw materials in manufacturing processes.

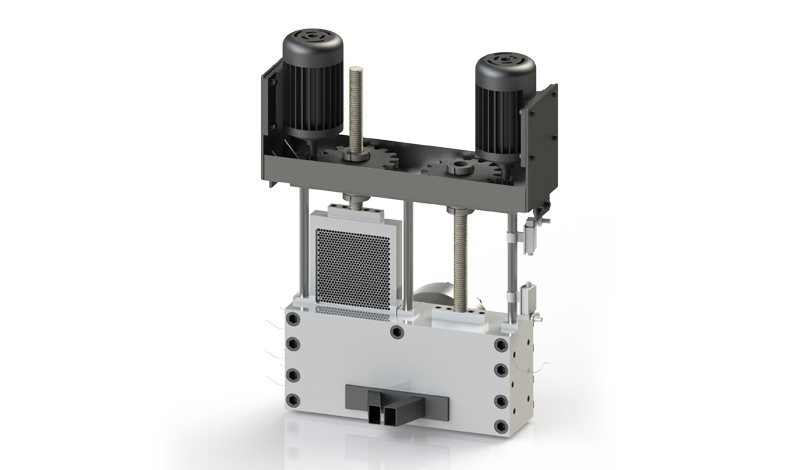

The plastic granule cutter operates by using a series of blades that shred plastic waste into small, uniform granules. These granules can then be used to create a variety of products, including plastic bottles, containers, and packaging materials. Additionally, the granules can be used as a raw material in other industries such as the construction and automotive sectors.

One of the major benefits of the plastic granule cutter is its ability to reduce waste and promote sustainability. By converting plastic waste into raw materials, this machine helps to reduce the amount of plastic that ends up in landfills and the environment. This, in turn, helps to preserve natural resources and reduce the carbon footprint of manufacturing processes.

Another advantage of the plastic granule cutter is its cost-effectiveness. This machine offers a sustainable and cost-effective alternative to traditional manufacturing methods, as it allows manufacturers to recycle their plastic waste and create new products without having to purchase new raw materials.

Furthermore, the plastic granule cutter is a highly efficient machine, capable of processing large volumes of plastic waste in a short amount of time. This efficiency helps to increase productivity and reduce the time and labor costs associated with traditional manufacturing processes.

In conclusion, the plastic granule cutter is a cutting-edge technology that is poised to transform the future of sustainable manufacturing. By reducing waste, promoting sustainability, and providing a cost-effective alternative to traditional manufacturing methods, this innovative machine is helping to create a more sustainable future for the environment and the manufacturing industry. As manufacturers continue to prioritize sustainability, the plastic granule cutter is sure to become an increasingly important tool in their arsenal.

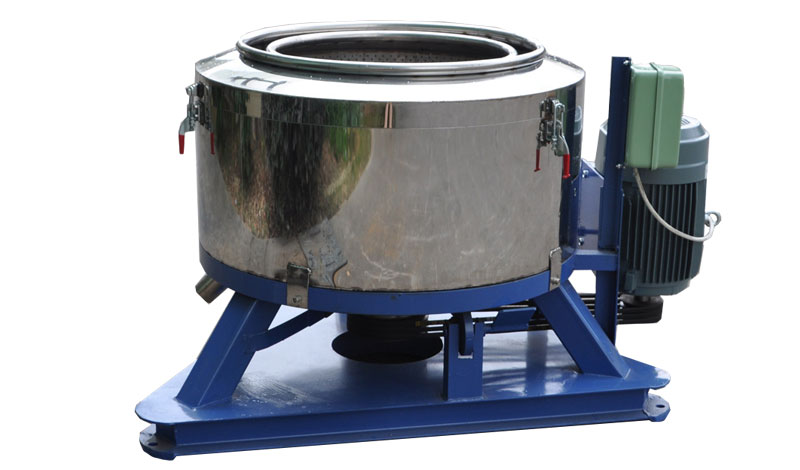

PLASTIC GRANULE CUTTER FPB-260 CAPACITY:550KG/H

Applicable to all kinds of engineering plastics,soft and hard plastics,long service life and uniform granulation,easy to operate. Adjustable Speed or frequency control speed is selectable.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3