Contact us

The ability to adjust cutting parameters is a pivotal f […]

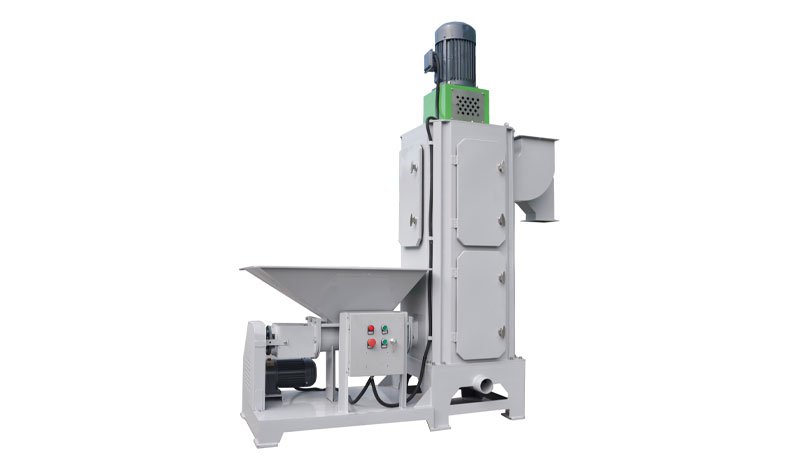

The ability to adjust cutting parameters is a pivotal feature of modern plastic granule cutters. It empowers operators to fine-tune the cutting process based on the specific properties of the plastic material being processed, leading to optimal results in terms of granule size, quality, and production efficiency. These adjustable parameters allow for versatility, making the plastic granule cutter suitable for a wide range of plastic materials and processing requirements.

Cutting Speed: The cutting speed refers to the rate at which the rotating blades engage with the plastic material. This parameter is adjustable to accommodate different plastic types and desired granule sizes. For softer plastics, a higher cutting speed may be suitable to maintain a clean cut, while for harder plastics, a lower cutting speed may be required to prevent excessive heat generation or blade wear. The ability to adjust the cutting speed ensures that the granule cutter can handle various materials without compromising on precision.

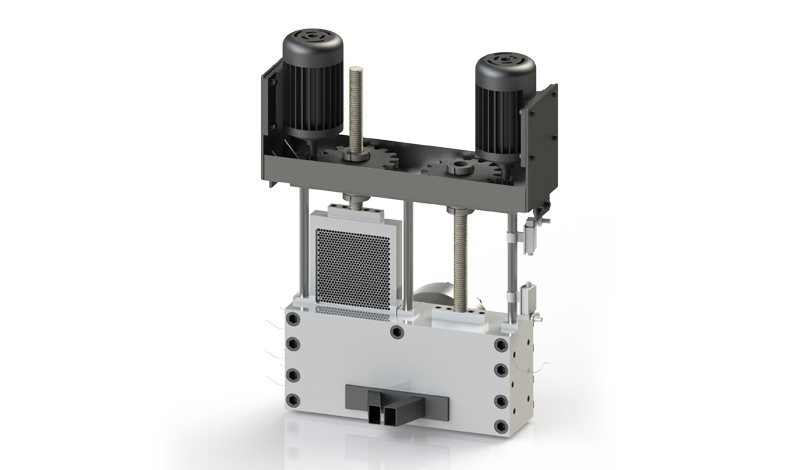

Blade Angle: The angle at which the cutting blades engage with the plastic material can significantly impact the cutting process. An adjustable blade angle allows operators to optimize the cutting action based on the specific plastic's hardness and viscosity. For some materials, a steeper blade angle may be necessary to achieve clean cuts, while a shallower angle might be more suitable for others. This parameter ensures that the granule cutter can handle plastics with diverse properties.

Feed Rate: The feed rate, also known as the throughput or material input rate, determines how quickly the plastic material is introduced into the cutting chamber. Adjusting the feed rate allows operators to control the amount of material being processed per unit of time. This parameter is crucial for maintaining a balance between production efficiency and granule quality. Too high a feed rate might result in inconsistent cuts, while a low feed rate could underutilize the machine's capacity.

Cutting Chamber Configuration: The design of the cutting chamber can influence the cutting process. Some granule cutters allow for adjustments in the cutting chamber configuration, such as the distance between the blades or the size of the cutting chamber itself. These adjustments are particularly useful when working with different plastic materials that may require specific chamber configurations to ensure optimal cutting performance.

Granule Size Control: Many advanced plastic granule cutters offer the ability to control the final granule size. This is essential for industries that require consistent granule dimensions for specific applications. Operators can adjust the cutting parameters to produce granules within a predefined size range, ensuring that the output meets the desired specifications.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3