Contact us

Plastic waste is one of the biggest environmental chall […]

Plastic waste is one of the biggest environmental challenges that we face today. It is estimated that more than 8 million tonnes of plastic waste enter our oceans each year, posing a serious threat to marine life and the environment. However, a new technology is emerging that could change the way we deal with plastic waste – the plastic washing recycling machine.

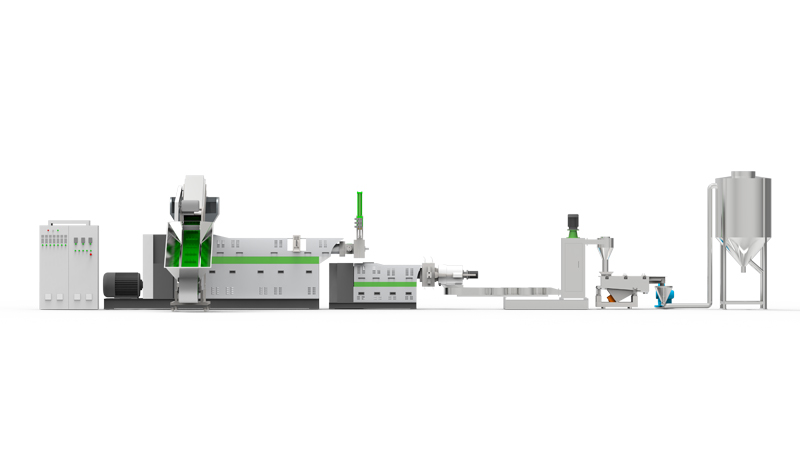

The plastic washing recycling machine is a sophisticated piece of technology that can process plastic waste and turn it into new products. The machine works by first washing and shredding the plastic waste into small pieces. The plastic is then melted down and extruded into pellets, which can be used to make new plastic products.

The advantages of this technology are manifold. Firstly, it offers a sustainable solution to the plastic waste problem, reducing the amount of waste that ends up in landfills and the environment. Secondly, it offers a way to create new products from plastic waste, reducing the need for virgin plastic production. Finally, it can create jobs and economic opportunities in the recycling industry.

However, there are some challenges that must be addressed before the technology can become widely adopted. Firstly, the cost of the machine must be competitive with traditional methods of plastic production. Secondly, the technology must be proven to be safe and reliable, with no harmful by-products or emissions. Finally, there must be sufficient supplies of plastic waste to feed the machine, which may require a shift towards more sustainable and circular models of plastic production and consumption.

Fortunately, there are already some companies and organizations that are leading the way in the adoption of this technology. For example, Veolia, a French waste management company, has developed a plastic washing recycling machine that can process up to 25 tonnes of plastic waste per hour. The machine is being used to create new plastic products, such as shampoo bottles and detergent containers, from recycled plastic.

In conclusion, the plastic washing recycling machine offers a promising solution to the plastic waste problem. While there are still some challenges to be addressed, the potential benefits of the technology are significant, and it offers a path towards a more sustainable and circular economy. By embracing this technology, we can help to create a more sustainable future for ourselves and the planet.

1.for PP PE film and woven bags washing.

2.Water tank is mode by stainless steel which is strong and durable.

3.500kg/h is attainable.The equipments are choosable for your need.

PP PE film cleaning line is suitable for crushing and cleaning of PP PE film. The structure design of this machine is reasonable, the connection is tight, and the integration of crushing, cleaning and dehydration is realized. The mill uses the film special cutter roller, the production efficiency is high, the noise is small, the operation is stable; The cleaning pool is made of stainless steel, durable, not easy to corrosion, according to the cleanliness of the material can choose single pool cleaning and double pool cleaning two modes; The dehydrator adopts high-speed rotating spiral dewatering, which can remove most of the water in the material and meet the needs of granulation

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3