Contact us

The process of separating recyclable plastics into usab […]

The process of separating recyclable plastics into usable material begins with the selection of suitable equipment. This is important to avoid contamination during recycling. The separation process can be either wet or dry. The wet method involves using float tanks, while the dry method utilizes air separation technologies. The first step is the removal of non-recyclable materials. Magnets and eddy current separators are used to separate metals from plastic. The second step involves washing and cleaning. Detergents and disinfectants are applied to clean the waste before the final step in recycling.

The process of plastic recycling begins with cleaning. The removal of impurities will help the process go much more smoothly. Some impurities can include product labels, adhesives, debris, food residue, and other contaminants. Then, shredded plastic is cleaned. This step can be achieved in several ways. A shredded piece of plastic is a more uniform particle size and can also help eliminate contamination. After cleaning, each component is examined for class and quality.

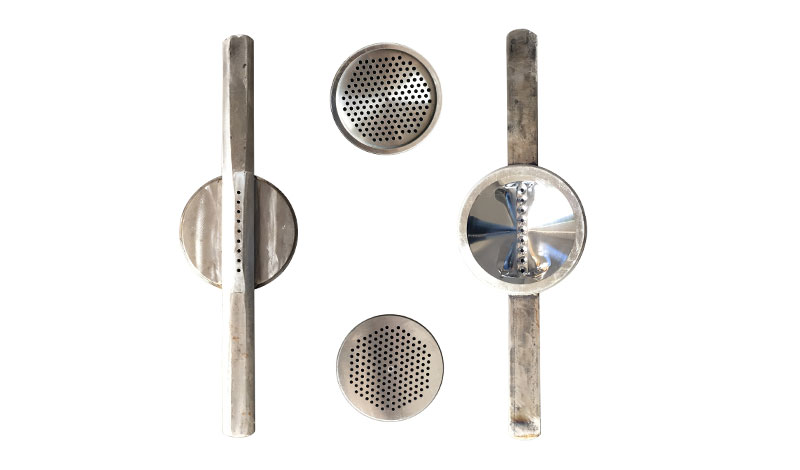

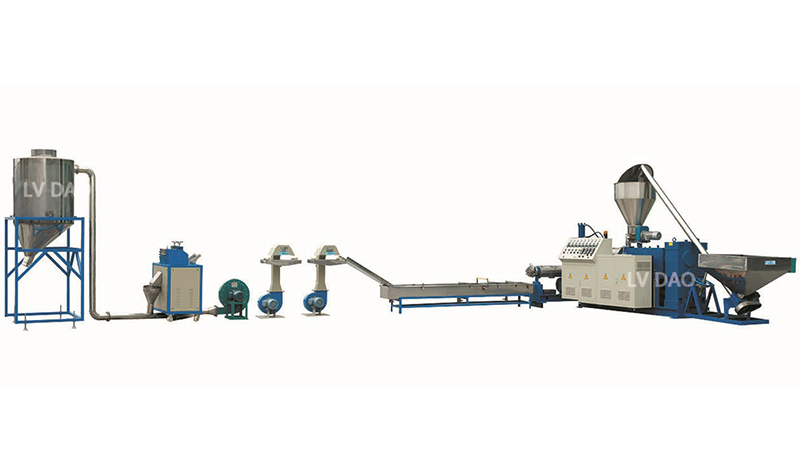

The third step involves melting plastic particles into pellets and selling them to manufacturers. This process is called extrusion. In the secondary recycling step, shredded plastic particles are turned into a useful product for manufacturers. These are then used to produce new products. In the tertiary recycling stage, the material is melted again, and the resulting pellets are sold to manufacturers. The final stage is called tertiary recycling, where the material is modified further by chemical means.

There are different types of plastic recycling equipment. The right one should fit the needs of your company. Some of these machines are designed to process various materials. Some are industrial and others are designed for home use. Regardless of the type, it's important to select the appropriate type for your operation. If you have an industrial-scale facility, you can purchase a single machine. In-line recycling will reduce the costs of waste disposal by more than 80 percent.

The right equipment is essential for a successful recycling operation. Aside from the appropriate equipment, the process of recycling plastic is crucial for reducing waste and increasing profits. Aside from reprocessing recycled materials, the process of separating recyclable materials includes a variety of other components. For instance, a vacuum cleaner can separate recyclable materials. Aside from that, it can also separate glass, aluminum, and stainless steel. A rotary dryer can separate waste from paper.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3