Contact us

Plastic mixer machines play a vital role in various ind […]

Plastic mixer machines play a vital role in various industries, including manufacturing, construction, and recycling. These machines are designed to blend and mix plastic materials, enabling the creation of high-quality plastic products. However, with numerous options available in the market, choosing the right plastic mixer machine can be a daunting task. To help you make an informed decision, this guide will outline key factors to consider when selecting a plastic mixer machine.

Capacity and Size:

The first step in choosing the right plastic mixer machine is determining the required capacity and size. Consider the volume of plastic materials you'll be working with and choose a machine that can handle your production needs. It's crucial to strike a balance between a machine that is large enough to meet your requirements and one that doesn't exceed your budget or occupy excessive space in your facility.

Types of Mixers:

There are different types of plastic mixer machines available, each suitable for specific applications. The most common types include batch mixers, continuous mixers, and static mixers. Batch mixers are ideal for small-scale productions, while continuous mixers are better suited for large-scale operations with a constant flow of materials. Static mixers, on the other hand, are often used for specialized applications. Assess your production requirements and choose the mixer type that aligns with your needs.

Mixing Quality:

The quality of mixing is crucial for producing consistent and homogeneous plastic blends. Look for a plastic mixer machine that offers high mixing efficiency and ensures uniform distribution of additives and fillers within the plastic matrix. Consider features such as mixing speed, mixing mechanisms, and the ability to handle different types of plastics. Additionally, check for any sample or demonstration options to verify the mixing quality before making a purchase.

Material Compatibility:

Different plastic mixer machines are designed to handle specific types of plastic materials. Some machines may be suitable for general-purpose mixing, while others are specialized for particular polymers or plastic additives. Ensure that the machine you choose is compatible with the materials you work with to avoid issues such as material degradation, poor mixing performance, or equipment damage.

Power and Energy Efficiency:

Efficient energy consumption is not only environmentally friendly but also contributes to cost savings. Look for a plastic mixer machine that is energy-efficient without compromising on performance. Consider factors such as motor power, energy-saving features, and overall power consumption to find a machine that optimizes energy usage while maintaining high productivity.

In conclusion, choosing the right plastic mixer machine requires careful consideration of capacity, types of mixers, mixing quality, material compatibility, power efficiency, maintenance, safety features, cost, and warranty.

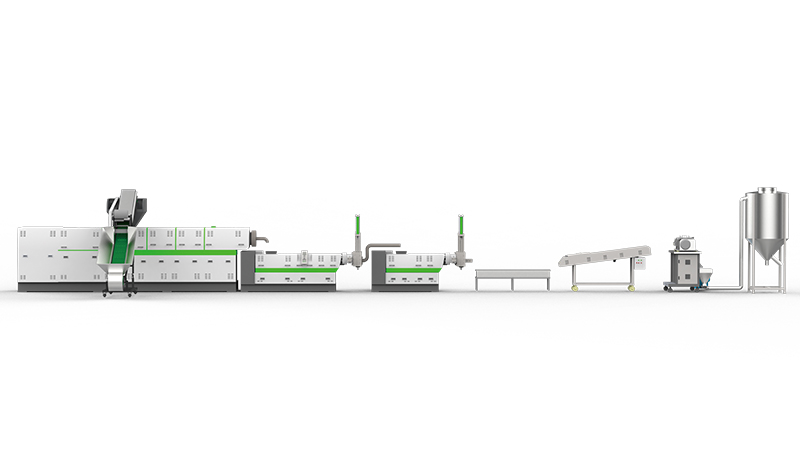

LOW SPEED COLORING AND MIXING MACHINE

It's used for the coloring and mixing with the low speed. Cubic: 25-200L.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3