Contact us

Having plastic recycling equipment can be a grea […]

Having plastic recycling equipment can be a great way to reduce your environmental footprint. Regardless of what type of plastic you are looking to recycle, there is equipment available to help. For example, you can use a shredder to break down smaller pieces of plastic or melt larger particles into smaller pieces. This will not only save you money, but also protect the environment from harmful pollutants.

Plastic is defined as a combination of resin and an organic substance. This means that any plastic that is not recycled will eventually end up in landfills. However, with the rising need for recycling, there are several different techniques to reprocess plastic into new products.

In the United States, for example, the Environmental Protection Agency estimates that a single plastic bottle can take up to 450 years to decompose. This means that, although the industry has been catching a lot of attention, there are still some challenges. These include challenges related to product acceptance in developing economies, which may limit the overall development of the industry. In addition, government initiatives in developed countries to promote recycled plastics are expected to contribute to the market's growth.

As with any type of recycling, there are a few key points to consider before starting a plastics recycling business. First, you need to decide on a location for your business. Then, you will need to find some lenders to finance your venture. Before you apply for financing, it's a good idea to compare interest rates and terms.

There are many types of plastics, including polyethylene, polypropylene, and polyvinyl chloride. These materials are separated into several segments, which determines which type of recycling machine you will need. You can either buy used or refurbished recycling equipment, which can be less expensive than buying new.

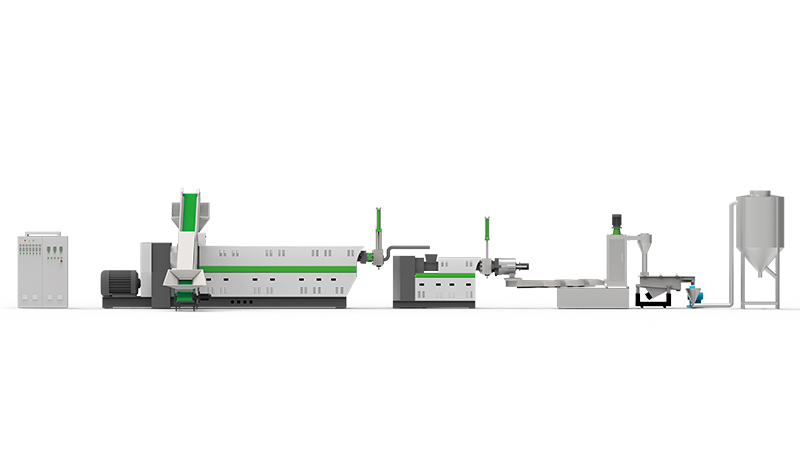

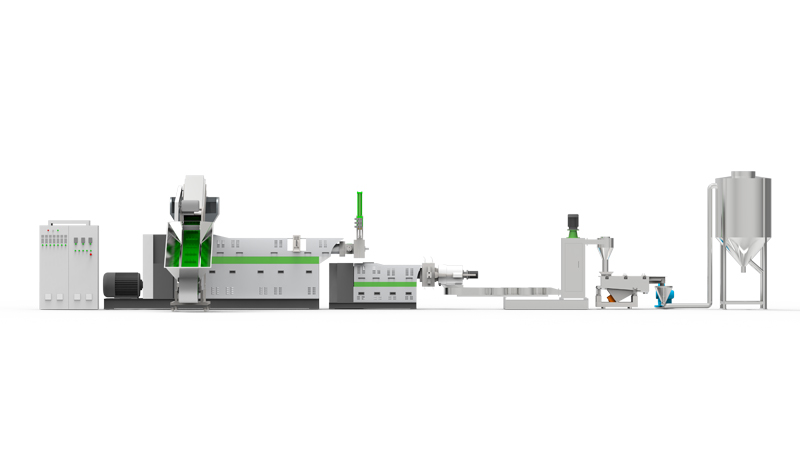

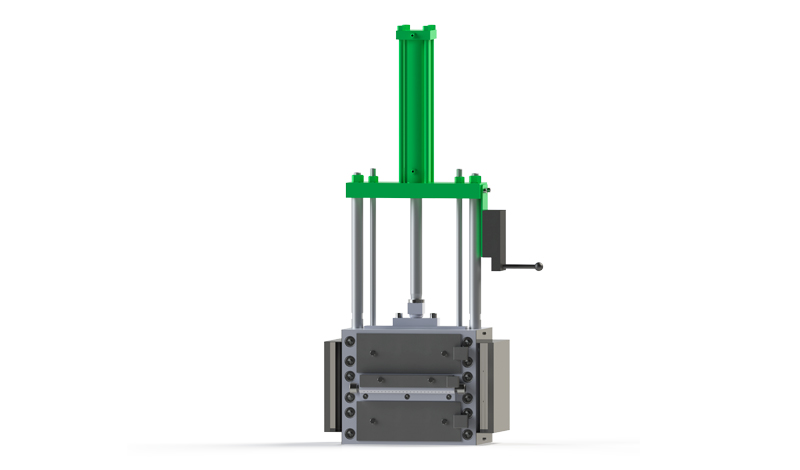

Some of the most popular plastics recycling machines are granule extruders and float tanks. These are both commonly used to separate materials by weight. A float tank is a common wet separation method, while a granule extruder can be used for directly reclaiming waste plastic.

In some cases, you will need to install a closed-loop system for your plastic recycling operation. This will take scrap from your processing line and allow you to sort the plastic into different grades. This process can be relatively simple and will enable you to reclaim a large amount of waste material. This will help you increase your productivity and ensure that the waste that you are collecting is being utilized properly.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3