Contact us

In a world grappling with the challenges of plastic was […]

In a world grappling with the challenges of plastic waste, innovative solutions are emerging to address the pressing issue of plastic pollution. One such solution is the plastic recycling machine—a revolutionary technology that transforms discarded plastic into valuable resources.

Plastic washing recycling machines are advanced systems designed to process plastic waste and convert it into reusable materials. They are equipped with cutting-edge technology and utilize a range of processes to achieve efficient and effective recycling. These machines can handle various types of plastic, including PET bottles, HDPE containers, and LDPE films, among others.

The first step in the plastic recycling process involves sorting and separating different types of plastic. This is accomplished through automated systems that use sensors and optical scanners to identify and categorize plastic materials. Once sorted, the plastics are shredded into smaller pieces, creating plastic flakes or pellets.

The shredded plastic is then washed to remove any contaminants such as dirt, labels, or residual liquids. This washing process ensures that the recycled plastic meets the required quality standards. Next, the clean plastic flakes are melted and extruded into thin strands, which are then cooled and cut into pellets. These pellets can be used as raw materials in the production of new plastic products.

The benefits of plastic recycling machines are multifold. Firstly, they help mitigate the environmental impact of plastic waste. By diverting plastic from landfills or incineration, these machines reduce the release of harmful greenhouse gases and conserve valuable landfill space. Furthermore, recycling plastic decreases the demand for new plastic production, which is energy-intensive and heavily reliant on fossil fuels.

Secondly, plastic recycling machines contribute to a circular economy. Rather than following the traditional linear model of "take, make, dispose," a circular economy focuses on continuous resource circulation. By recycling plastic and reintroducing it into the production cycle, these machines promote resource efficiency and sustainability. This closed-loop approach reduces the extraction of virgin resources and minimizes waste generation.

Moreover, plastic recycling machines offer economic opportunities. The recycled plastic pellets can be sold to manufacturers who use them as feedstock for the production of various plastic products. This not only generates revenue but also creates jobs in the recycling industry. As the demand for recycled plastic grows, so does the market for plastic recycling machines, leading to further economic growth and innovation.

In conclusion, plastic recycling machines offer a transformative solution to the global plastic waste crisis. By turning trash into treasure, these machines contribute to environmental preservation, resource efficiency, and economic growth. However, addressing the challenges associated with plastic waste requires concerted efforts from all stakeholders. By investing in technology, infrastructure, and education, we can unlock the full potential of plastic recycling machines and create a more sustainable future for generations to come.

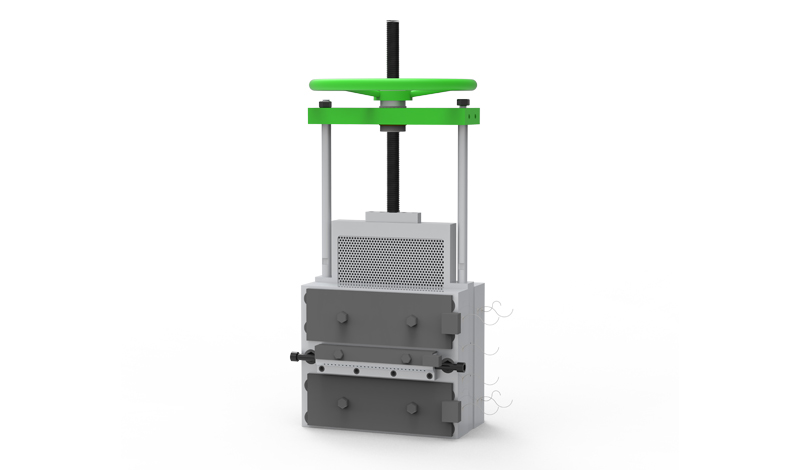

Suitable for crushed material,sheet material cleaning,stainless steel material,long service life.

The washing machine is suitable for cleaning the plastic flakes after crushing. The main body is made of 304 stainless steel material, not easy to rust, greatly increase the service life. There are two models of 100kg and 200kg, and you can choose the size according to your needs. When the machine is running, you can add clean water directly. If the raw material is dirty, you can also add cleaning agent. The cylinder contains a stirring rod, which removes impurities on the surface of the material by friction stirring. The model has simple structure, simple operation, no need to install, power can be used. Cleaning time can be determined according to the need.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3