Contact us

A Plastic Granule Cutter is a necessary tool in many ca […]

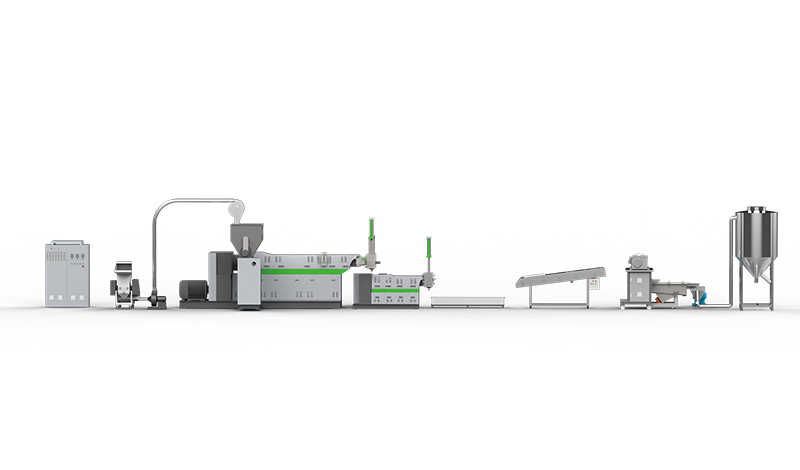

A Plastic Granule Cutter is a necessary tool in many cases. The process of granulation requires that several pellets are extruded at the same time. This is done by the use of an extruder, which is a device that feeds plastic pellets through a nozzle. The process of making pellets can be very time consuming. This is why it is best to buy this type of plastic recycling machine to simplify the work process.

There are many different types of plastic granule cutters available. There are two types of extruders, those that feed pellets into a hopper and those that spit the pellets out. You should consider your needs carefully when purchasing a new plastic cutting machine. This is because the amount of materials to be recycled will play a part in the type of cutter you purchase. A heavy duty unit would be required if you need to make large numbers of balls or if your business deals with large pieces of plastic.

A heavy duty plastic pellet cutter is capable of making a ball every sixty seconds. This kind of speed is needed for high volume plastic strips used for making granulated fertilizer. A smaller unit could take a much longer time to finish one single ball. Although there are some compact models that are capable of completing the work faster than the average industrial unit, these are usually for smaller operations only.

Industrial Plastic cutting machines offered by different companies are equipped with a variety of features. Some have a capacity of producing one ball every second while others can cut up to seven balls an hour. The different kinds of models also vary in terms of their size and capacity. Some of the smallest machines are even marketed as kitchen cutters while those meant for industrial uses are larger and tougher.

The most basic models are designed with simple controls. These units have a handle and a blade. Some have separate controls, while other types operate both ways. More expensive models come with a remote control and a knife, which allow the operator to cut through the plastic at a greater distance. A plastic pellet cutting machine with such functions can work independently or as part of a large machine that produces high volumes of materials.

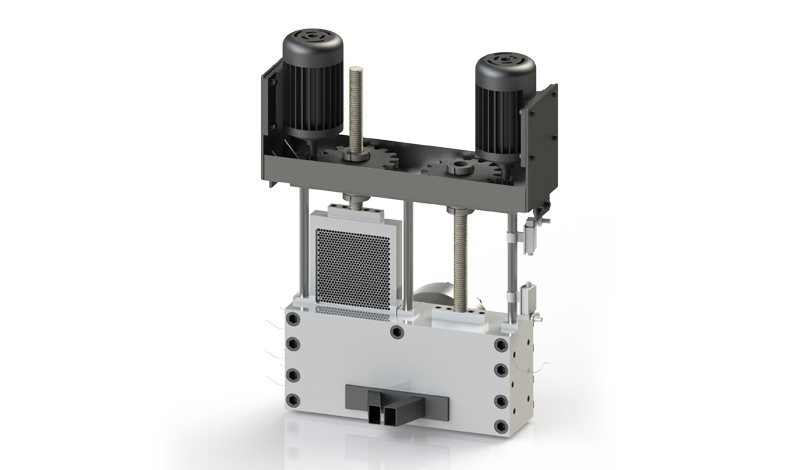

There are two common varieties used to make granules. The first type, called the traditional chipping machine, cuts through the material using high grade steel blades. This type usually comes with an attached knife which enables the operator to move the blade along the surface of the granule while the blades are used to cut the material. High grade steel and aluminum are the materials commonly used for this kind of cutting.

The second variety is the heavy duty plastic pellet cutter work system. This is almost like the traditional chipper but it needs a different approach in working. The result is that it generates a higher volume of materials and consumes less time. Because of these qualities, it is becoming more popular for industrial applications.

Plastic pellets are made by melting plastic in a heated environment. This melts the plastic into small beads or pieces. A special device stirs the melted plastic to mix it with a liquid medium. The plastic is then compressed to form pellets which are aerodynamically shaped. These pellets are then discharged into a chute or tube with a high efficiency pulley system, enabling the material to be sucked into a chute or conveyor belt for the production of plastic pellets used in making pellets for plastic recycling.

The third variety is a rubber roller cutter. Like the plastic cutting machine, it works on the principle of the mixing of hot and cold materials to create a particular thickness. Instead of cutting the material directly, it slices a thin film from the surface of the material. The main difference between the rubber roller and rubber cutter is that it uses an electric current to cut through the material using a rotating cutter blade. This kind of mechanism differs from the rotating cutters used in sawing that causes slippage. It also produces more pellets per cycle than the other kinds of cutters.

The last variety is the gas-powered plastic extruder. This kind of equipment functions under the principle of high-pressure gas firing. The air is introduced to a chamber where the pellets are ready to be extruded. Once the pellets are extruded out, the air is compressed once again to push the melted plastic up into a tube. This is one reason why gas extruders are more efficient than electric extruders.

Aside from the three common varieties of cutters, there are also some other types of extrusion machines that you can use for your plastic production. If you want to purchase a gas-powered machine, check if the gas comes in separate containers or cans. Some manufacturers bundle gas cartridges in one unit to save space and money. You may also want to check the cooling system of the plastic granule cutter. Make sure that its belt cooler prevents overheating or burn-up of sensitive parts.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3