Contact us

What is a Plastic recycling machine? This articl […]

What is a Plastic recycling machine? This article will explain the methods of recycling plastics, their costs, and how they can be used for energy recovery. The following are some of the most common types of plastic recycling machines. You should also consider how much space a machine will require. Plastic recycling machines are usually expensive. The cost of operating one depends on how much plastic it can recycle. Some plastics may require a larger area than others, but they are still worth the price.

Process of recycling plastics

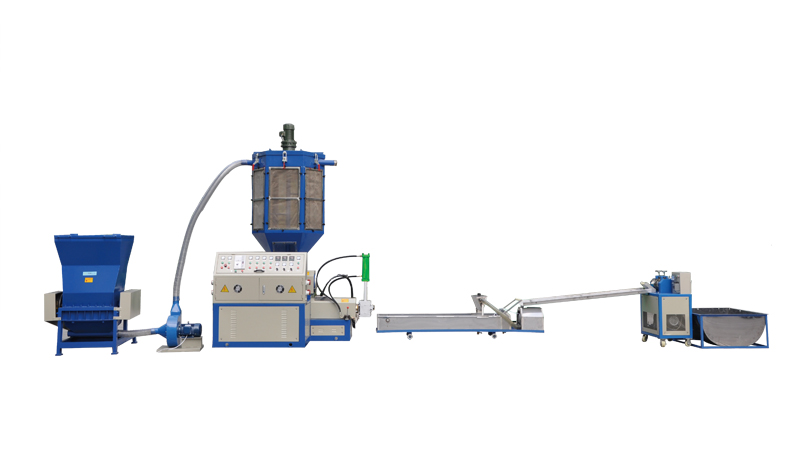

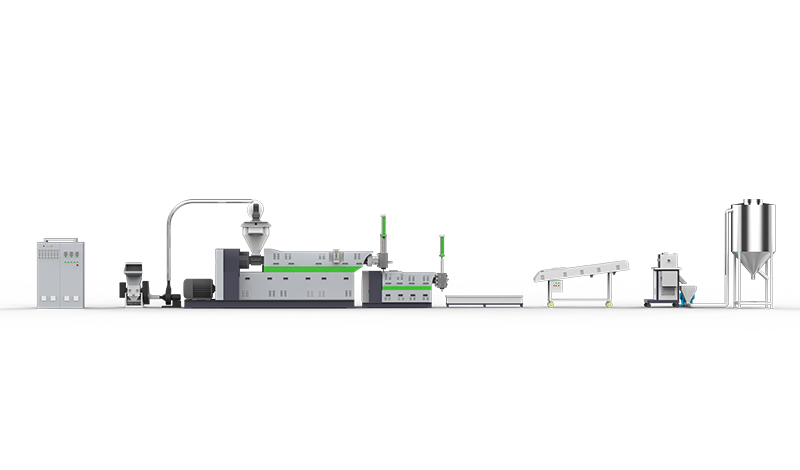

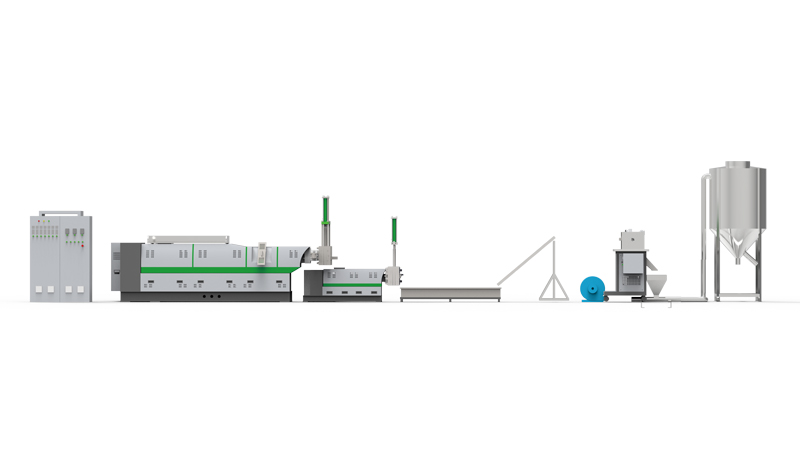

The Process of Recycling Plastics with a Plastic Recycling Machine is a comprehensive approach for processing waste plastics and materials. The machine can be integrated to handle all plastic recycling requirements, from collecting scrap plastic to granulation. For maximum efficiency, recycling mills include all required processing equipment, including washing, sorting, and drying equipment. Some plastic recycling machines also offer the option to recycle PET in-house waste and PET flakes.

The plastic particles are sorted based on their quality and class. The density of the plastic particles is the first quality to be determined. Thinner particles will float while the thicker ones will float at the bottom of the wind tunnel. The plastic particles are then sent to the next stage of processing, called compounding. In this step, the plastic particles are transformed into materials that can be reproduced by manufacturers.

Methods of recycling plastic

There are different types of plastic, and understanding the difference between the different types is an important part of the plastic recycling process. The recycling symbols on products indicate the type of resin that they are made of. Certain plastics are not recyclable, while others can be reused in many ways. For example, PETE, or polyethylene, is widely recycled. However, other types are not so easily recycled, and they must be disposed of correctly.

The first step in the recycling process is to sort waste according to its properties, such as size and purity. These particles are then crushed or melted to create pellets. Depending on their qualities, not all of the plastic recycling process can be performed at one location. In that case, different grades are sent to different recycling facilities. The following steps are important for separating recyclable plastics. They should be separated according to their purity, melting point, and color.

Costs of recycling plastics

The costs of recycling plastics are higher than those of virgin plastic materials made from oil. Some methods of recycling plastic are easier than others, such as melting or reprocessing. Some recycling methods have longstanding problems and the costs are higher than the materials themselves. Less than ten percent of plastic is recycled. The public may not be aware of these challenges, but these problems have been present for decades. It is not clear how much of the plastic we throw away can be recycled.

The environmental and financial costs of recycling plastics have caused many to abandon this process altogether. The costs are largely due to the lightweight nature of plastics, the cost of transportation, and the resulting pollution. However, some markets are rebounding. In Portland, for example, a nonprofit group provides services for landfilling, recycling, and waste-to-energy. They saw a 39% to 325% increase in their prices for different types of materials from July to January. However, these costs are still higher than they were just a year ago.

Energy recovery

Scientists at the University of California, Irvine have developed a new way to recycle polyethylene waste into liquid fuel. Working with the Shanghai Institute of Organic Chemistry, the researchers converted plastic into liquid fuel by removing and adding chemical bonds. The resulting fuel is suitable for cars and other industrial purposes. The process is cheaper than traditional methods of recycling plastic, which can cost as much as $4,000 per tonne. And unlike mechanical recycling, chemical recycling does not require pre-sorting the waste.

The big oil companies, which make the petrochemicals used in plastic, are increasingly turning to startups with the technology. These companies claim to turn trash into fuel and resin. But what exactly do they do with the plastics after they've been recycled? Some recyclers have renamed the process "energy recovery" to make it more palatable to the public.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3