Contact us

Plastic pollution has emerged as a global environmental […]

Plastic pollution has emerged as a global environmental crisis, posing severe threats to ecosystems, wildlife, and human health. To tackle this pressing issue, various solutions have been devised, and one such crucial tool in the fight against plastic pollution is the plastic pelletizing line. This essay explores the significance of plastic pelletizing lines, their operation, and the impact they have in addressing plastic pollution.

What is a plastic pelletizing line?

A plastic pelletizing line is a specialized industrial machinery system designed to transform plastic waste into small, uniform pellets. It involves a series of processes, including shredding, washing, drying, and extrusion, to convert plastic waste into a reusable form. The resulting plastic pellets can be utilized as raw materials in the manufacturing of new plastic products.

How does a plastic pelletizing line work?

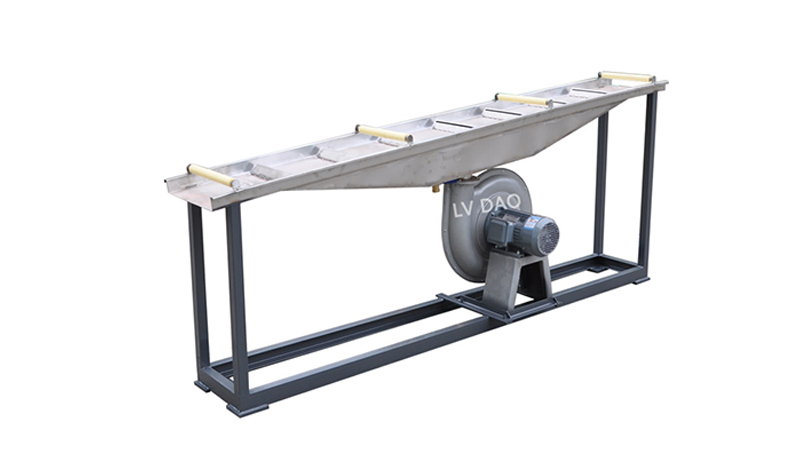

The process begins with the collection and sorting of plastic waste, ensuring that contaminants are removed. Next, the plastic waste undergoes shredding, which breaks it down into smaller pieces. These shredded pieces are then washed thoroughly to eliminate impurities such as dirt, debris, and residual chemicals. The cleaned plastic is subsequently dried to remove moisture, which can affect the quality of the pellets. Finally, the dried plastic is fed into an extruder, where it is melted and forced through a die to form cylindrical pellets. The pellets are then cooled, solidified, and ready for reuse.

What are the benefits of plastic pelletizing lines?

a) Plastic waste reduction: By converting plastic waste into pellets, plastic pelletizing lines enable the recycling and reuse of materials that would otherwise contribute to landfills or end up in the environment.

b) Resource conservation: The production of plastic pellets reduces the demand for virgin plastic materials, conserving valuable natural resources such as fossil fuels and reducing energy consumption.

c) Environmental preservation: By preventing plastic waste from polluting ecosystems, plastic pelletizing lines help preserve biodiversity and protect wildlife, especially marine life, from the harmful effects of plastic pollution.

d) Economic opportunities: Plastic pelletizing lines contribute to the creation of a circular economy, generating employment opportunities and fostering the growth of a sustainable recycling industry.

e) Carbon footprint reduction: Recycling plastic waste through pelletizing lines helps reduce greenhouse gas emissions associated with the production of new plastic materials, thereby mitigating climate change impacts.

The plastic pelletizing line plays a pivotal role in addressing the plastic pollution crisis by transforming plastic waste into valuable resources. Its ability to convert plastic waste into reusable pellets contributes to waste reduction, resource conservation, environmental preservation, and economic opportunities. However, overcoming challenges and fostering collaboration among stakeholders are essential to maximizing the impact of plastic pelletizing lines and moving towards a more sustainable future.

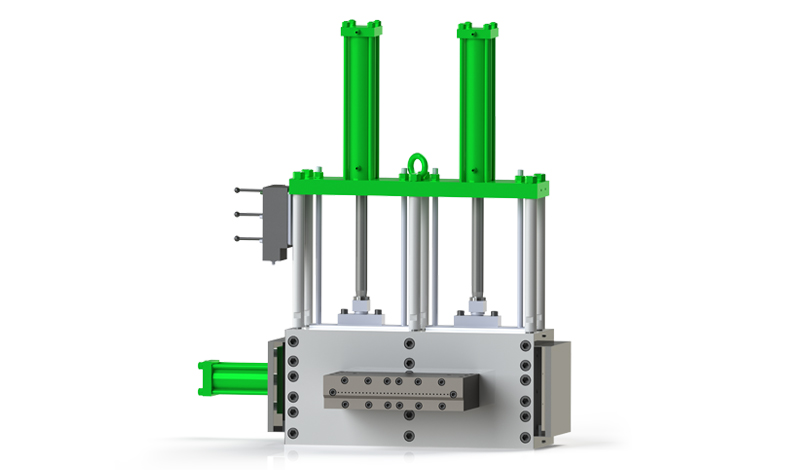

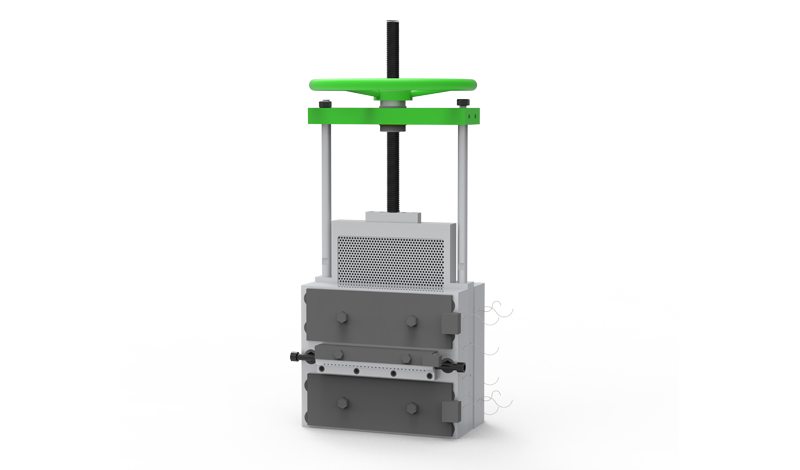

Use 45# steel, split plate and back plate burnt hard alloy

Yuyao Lvdao Plastic and Rubber Machinery Co., Ltd is well known Manual Screen Changer manufacturers and industrial Manual Screen Changer suppliers in China. We can make the products following the customers' requirements,like the shape,size,color,logo and other spec details. According to the different characteristics of various plastic materials to develop a batch of new products, maximize to meet the needs of customers.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3