Contact us

Whether you are in the business of producing pla […]

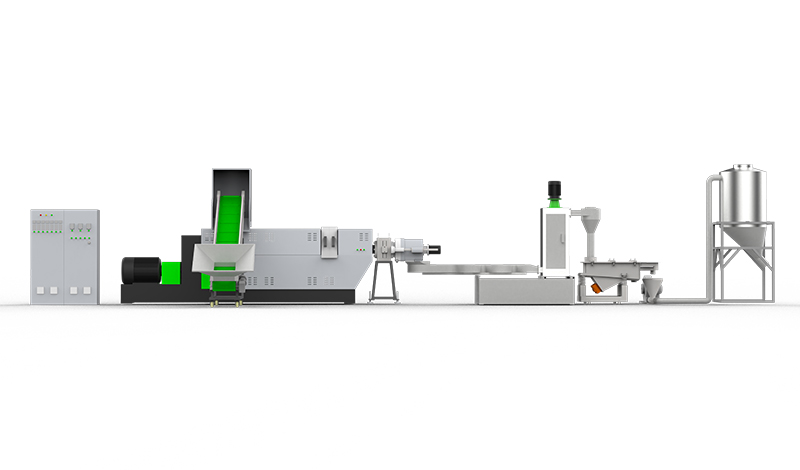

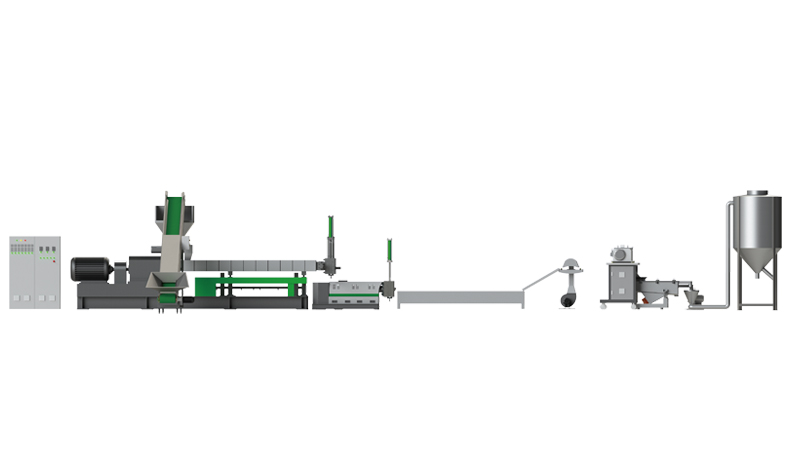

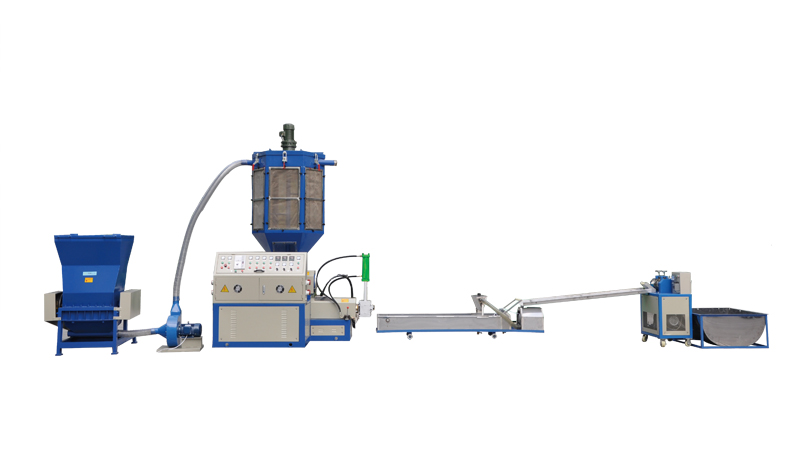

Whether you are in the business of producing plastics for packaging or processing, an OEM plastic crusher is a necessity. The main function of a plastic crusher is to shred a wide range of plastics into granules. It is also a cost-effective tool in the plastics recycling line. It has a high output capacity and a small footprint. It is also easy to operate and maintain. It is suitable for the production of plastics, pellets, and other recycling materials.

It has a well-crafted, robust welded steel construction that withstands high loads and wears. It features a hydraulic workstation that is tightly integrated with the shredder chamber. It can be configured to work in conjunction with a washing and pelletizing line. This enables you to save space and improve efficiency. It also helps to prolong the lifespan of the blade. The inlet for wet crushing is a nice touch. It lowers the temperature of the blades and ensures a smooth and even cut.

Aside from the actual shred, the best part about this machine is its low energy consumption. The hob rotates at a medium speed so that it does not heat up too quickly. In addition, the rotor can be surface or hardened. It can be equipped with a water cooling system if you need it to. The motor has an overload protection device. It can be operated on a variety of voltages. It is also very quiet.

The machine has an ingenious rotor that has a V-shaped design. It is equipped with a solid steel shaft that is treated with quenching treatment. It has a screen that is made of 10mm thick steel. It has a main axis that is driven by a gearbox. It also has a bearing house installed outside the crusher chamber to prevent dirt from entering the chamber. It can also be disassembled in the event that the blade needs to be replaced.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3