Contact us

A Plastic Pelletizing Line has an important role in imp […]

A Plastic Pelletizing Line has an important role in improving the productivity of various businesses involved in the manufacture and transportation of feed components, finished goods and finished products. Feed components are all raw materials that are required in the production process of almost all the business sectors that depend on petroleum. For example, a Feed material manufacturing unit focuses on producing high quality feed pellets for livestock. At the same time it also wants to make sure that the finished product is of premium quality. The latest developments in the area of Plastic Pelletizing have helped this industry to meet these challenges and improve its processes and productivity.

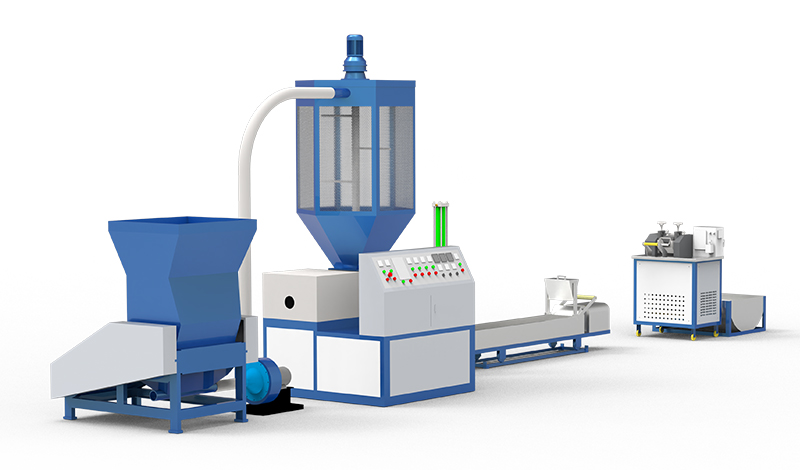

The plastic pelletizing line is used for both initial steps involved in the manufacture of the feed products like the manufacturing of the solid waste and the making of the liquid fuel. In the process of manufacturing of the solid waste, the solid particles are broken down by the use of a rotary shredder, after which they are transferred into a chute or hopper by the use of a screen. This process then produces pellets. These pellets are loaded into an injection mold, where they undergo heating in the presence of an ultraviolet light source and hot air. This then makes the pellets swell in the chamber, before being ejected from the mould onto a tumbler roller that transports them on to a horizontal surface.

On the other hand in the process of making of the liquid fuel, the plastic pellets are melted in the presence of a mixing drum and then poured into a vacuum tank. After the mixture is cooled down, it moves on to a cold roller assembly, where it melts once again and turns into a pellet. This is then further transported to a packaging line by the use of a screw extruder. During the transportation of the finished product, the plastic pellets will pass through the nozzle on to a packaging conveyor belt. In the final phases of manufacturing, the plastic pellets will be shredded using a blade shredder.

The plastic pellets used in the production of the fuel also come in varying sizes. This is because the pellets are required to be broken down into very small pieces before they can be discharged into a chute or hopper. The smaller sized pellets require the least amount of manual work while at the same time providing higher rates of speed. This is why the most popular plastic pelletizing machine is the double barrel extruder variety.

Pelletizing offers complete solutions for the product categories mentioned above.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3